by Michael Garnham | Sep 4, 2014 | Articles, Ewon Netbiter, Products, PROFIBUS

When delegates visit the IDX Academy in South Africa for training, they are always encouraged to bring their piece of equipment along with which they might be having trouble getting communications going – or even just understanding the data it produces. At the...

by Michael Garnham | Sep 3, 2014 | Anybus ComBricks, Case Studies, Permanent Monitoring, Products, PROFIBUS, Solutions

Bandini Cheese is a South African cheese manufacturer supplying their products to numerous pizza restaurants around South Africa. They are always striving to provide the highest quality products and this ethos can be seen in other aspects of their manufacturing...

by IDX Team | Sep 2, 2014 | IDX News

The Africa Engineering Week is running this week from 1-5 September 2014 at the Doornfontein Campus of the University of Johannesburg. The event aims to showcase various disciplines of Engineering and encourage scholars to consider choosing a career in the Engineering...

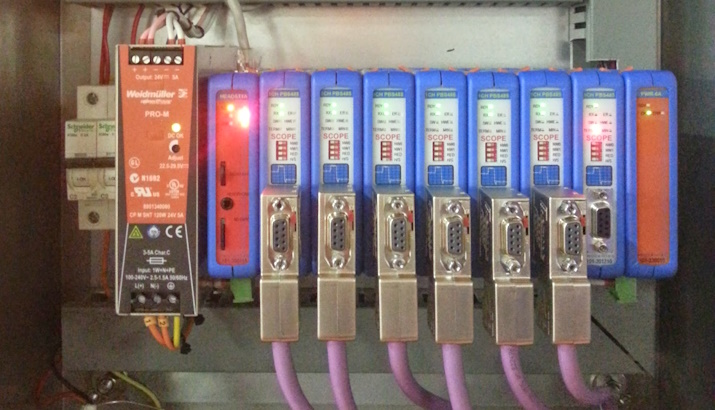

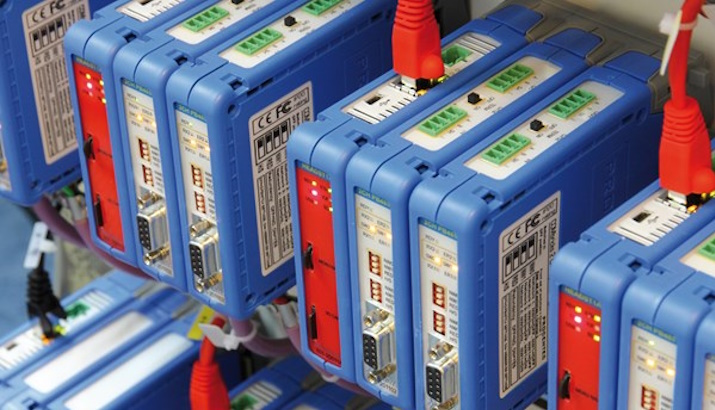

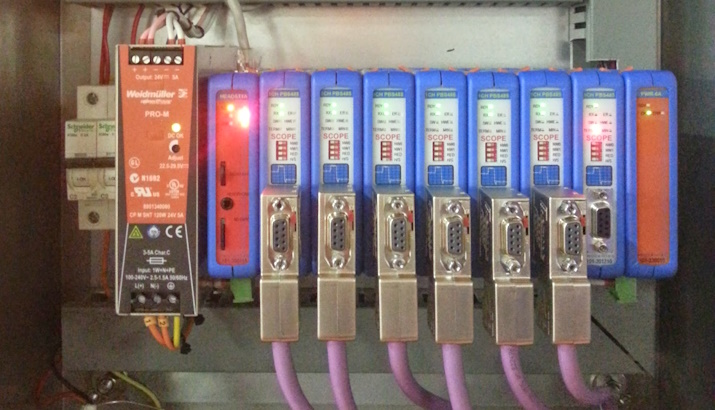

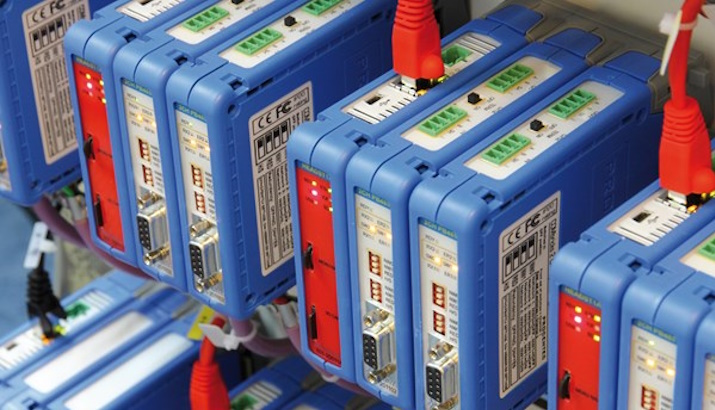

by Michael Garnham | Aug 29, 2014 | Anybus ComBricks, Anybus ProfiTrace, Articles, Diagnostics, Permanent Monitoring, Products, PROFIBUS, Solutions

Sometimes the intermittent and unexplained failures of a PROFIBUS network can only be explained as one thing: “My system has caught the PROFIBUS virus!” This is how it must appear to someone who doesn’t have the right tools to analyse and monitor...

by Michael Garnham | Aug 27, 2014 | Anybus ComBricks, IDX News, Products, PROFINET, Technologies

The PROFIBUS/PROFINET Competence Centre of South Africa recently ran two Certified PROFINET Engineers in a row at Siemens South Africa. Using tools such as Netilities from PROCENTEC, the delegates were able to quickly understand the structure of their PROFINET...