Insights from the PROFIBUS wire (understanding equipment behaviour)

This blog is a by-product of a recent project to investigate

and validate the sequence of events on some electrical Switch-gear where the

SCADA and Switch-gear communicate over PROFIBUS DP. This was done by examining what was happening "on the PROFIBUS wire" (Actually PROFIBUS DP has two wires, a red one and a green one!).

It also brought into focus the idea that analysis of process data as it appears “on

the wire” could have many operational and maintenance benefits – achieved

without additional loading or complication for the associated SCADA. While it is true that modern field-bus and industrial Ethernet systems support the use of intelligent field devices which can provide access to configuration and diagnostic information via FDT and similar engineering tools there is a an effortless simplicity to gaining insight on the wire through independent means. This is especially true when comparing events from different sensors or items of equipment to determine cause-and-effect relationships and accurate time sequencing.

Now we go back to the actual investigation. An intermittent logic fault reported by the

SCADA suggested that the feedbacks from Switch-gear contactors were sometimes reported in

the wrong sequence causing incorrect operation. By recording data change at the wire level we were to monitor the behaviour of ten pumps which all

shared a common IO template and test this hypothesis.

The pumps all had an IO template as shown below:

Signal Description

|

Signal

Name

|

Signal

Type

|

(XB01)

Feedback Signal – Contactor is Open

|

FBOPN

|

DI

|

(XB02)

Feedback Signal – Contactor is Closed

|

FBCLS

|

DI

|

(XB08)

Ready (Start)

|

READY

|

DI

|

(XB20)

Some Fault condition that will prevent normal operation

|

FLT

|

DI

|

(XB04) Remote

Operation of Pump is enabled

|

REMOTE

|

DI

|

(XQ01)

Current that flows when pump is operated (0 to 100%)

|

CURRENT

|

AI

|

(YB01)

Open Command (pulse of width of 2.0seconds)

|

CMD OPN

|

DO

|

(YB02)

Close Command (pulse of width of 2.0seconds)

|

CMD CLS

|

DO

|

BEFORE STARTING A

PUMP

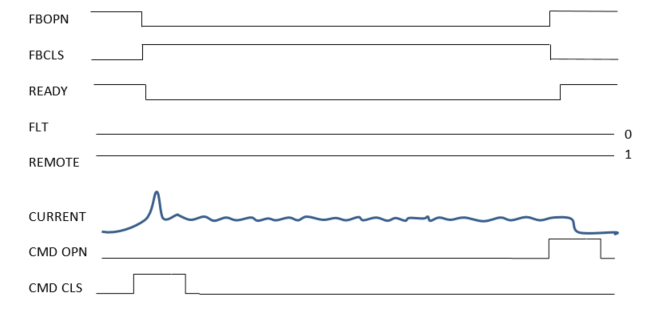

If we view what happens on the

PROFIBUS wire over a period when a pump is started and then stopped we expect

to find initially (an idle pump in the "off" state):

(INPUTS)

FBOPN =

1 This implies that the pump is

stopped (not energised)

FBCLS = 0 This implies that the pump

is stopped (not energised)

READY =

1 This indicates that the pump is

available to be started

FLT = 0 This indicates that there

is no local fault that might prevent operation

REMOTE = 1 This indicates that the SCADA is enabled to

operate the pump

CURRENT = 0 As the pump is stopped there is no current

(OUTPUTS)

CMD OPN = 0 There

is no active command to stop

CMD CLS = 0 There is no active command to start

WHEN STARTING A PUMP

When a pump is requested to start

we expect to see a 2-second duration pulse, ⸥⸺⸤ (0 to 1 and then 1 to 0 transition) on

CMD CLS which will cause:

(INPUTS)

FBOPN = 0 This implies that the pump

is now started (energised)

FBCLS = 1 This implies that the pump

is now started (energised)

READY = 0 This implies that the pump

is started (energised) or is not able to start

REMOTE = 1 This indicates that the SCADA is enabled

to operate the pump (does not change)

CURRENT > 0 For

a few hundred milliseconds there will be a high start-up current before the current drops back into

normal operating range ( 0 > CURRENT <= 100)

(OUTPUTS)

CMD OPN = 0 There

is no active command to stop

CMD CLS =

0 After the 2-second-wide pulse there

will be no active command present.

During normal pump operation the value

for CURRENT changes while all other signals remain in the same state (as

above).

WHEN STOPPING A PUMP

When a pump is requested to stop

we expect to see a 2-second duration pulse, ⸥⸺⸤ (0 to 1 and then 1 to 0 transition) on

CMD OPN which will cause:

(INPUTS)

FBOPN = 1 This implies that the pump is stopped

(not energised) was previously 0

FBCLS =

0 This implies that the pump is

stopped (not energised) was previously 1

READY = 1 This indicates that the pump is again

available to be started – was previously 0

FLT = 0 This indicates that there

is no local fault that might prevent operation (unchanged)

REMOTE = 1 This indicates that the SCADA is enabled

to operate the pump (unchanged)

CURRENT = 0 Within

one or two scans, there is no current as the pump is stopped.

(OUTPUTS)

CMD OPN = 0 After

the 2-second active pulse has completed the signal return to zero

CMD CLS = 0 There is no active command to start

This expected sequence is described

below.

|

| The expected sequence for pump starting, running and stopping |

Our approach was to passively listen on the PROFIBUS network

and capture the traffic between the SCADA and the Switch-gear, knowing that the commands

would be contained in the CYCLIC DATA EXCHANGE OUPUT issued by the SCADA to the

Switch-gear and that all the feedbacks would be contained in the CYCLIC DATA

EXCHANGE INPUT received by the SCADA from the Switch-gear. Also by creating

filters to watch for specific data changing we could limit the amount of data

that we needed to record.

As the intermittent error conditions could be days apart we

choose to install a monitor at the remote site and then upload the recorded

data to our office where we developed an offline tool for analysis and

reporting – a tool that created a simple-text-log of when signals changed and

the duration of time that had elapsed before the change occurred. It also

created an excel spreadsheet that showed the state of all related signals for

every DATA EXCHANGE message that contained any data that had changed.

|

| PROFIBUS Monitoring Tool with Remote Monitoring |

The PROFIBUS monitoring tool made use of PROCENTEC

PROFITRACE to connect passively onto the PROFIBUS network and to log the data

to disk.

The above screen shows a filtered

view of recorded PROFIBUS messages that contain the I/O data exchanged between

the PLC Master (Station Address:1) and the LV Switch-gear PROFIBUS Slave

(Station Address:30).

All outputs from PLC are

exchanged in a single message (SRD HIGH) while the inputs from the LV

Switch-gear are exchanged in a single message (DL). From the I/O Schedule it is

possible to extract the I/O for each pump and analyse when values change and to

measure the duration of time before a change occurs.

The next picture (an extract from an Excel

spreadsheet report for one of the pumps highlights normal expected behaviour

from just before a START and until just after a STOP.

|

| An example of Excel Spreadsheet produced for a pump operation : start, high-current, normal current, and stop |

THE IDEA OF A GENERAL PURPOSE TOOL FOR OPERATIONAL UNDERSTANDING

This blog will not go into any detail on the project finding but will rather indicate what the author saw as a general-purpose tool and benefit from passive listening on the wire (in this case PROFIBUS but it could be MODBUS or some industrial Ethernet) independent of the host SCADA system.

- Listening on the wire, independently, provides a single accurate version of what information was shared between the SCADA and Switchgear Station – with timing and detail at the same resolution of raw information transfer. When high-level systems log and report events there is no guarantee that they have the same accuracy as they may be subject to slower cycle times and asynchronous task execution and reporting.

- Determination of the exact sequence of events is made possible. Changes in feedbacks can only be reported with the INP message while commands are only transferred in OUT messages. This makes sequence of event analysis straight forward.

- What was very insightful was the high-speed-capture of the start-up current which could be as much as ten times the normal operating current. As these start-up currents are very short in duration, a few hundred milliseconds, it is possible that they are typically not seen in any SCADA logs. This suggests that very useful statistics and profiles of start and stop operation could be captured in this way and be provided to asset optimisation and equipment maintenance applications for analysis and operational intervention. This can be achieved without any load on the SCADA and by not requiring the SCADA to have to have much faster scans to capture these transients.

- Hence there is the real sense that this type of non-intrusive data recording and analysis may have many valid use cases – suggesting that there is more to PROFIBUS diagnostic monitoring than just the statistics of physical network faults and configuration issues – what the data is doing on the wire may provide useful insights not easily acquired from SCADA or the PlantData Historian that typically receives its data from the SCADA.

If you have any questions or comments you are invited to

contact the author daveb@idx.co.za