IDXOnline has an exciting solution in development to solve a long-standing challenge which involves collecting plant data directly from the Siemens PLC as opposed to from the WinCC OPC Server.

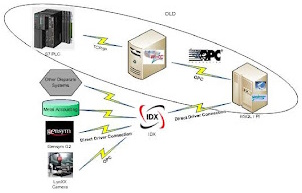

Out with the old:

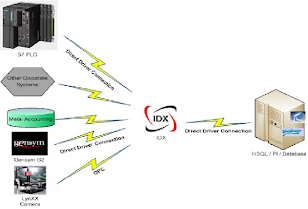

In with the new:

How will we achieve this?

IDX has obtained a dll package from one of our partners that can communicate with a Siemens PLC via TCP/IP. The package is suitable to be incorporated into the IDX runtime as a driver module and thus will work like any other IDX driver module and will enable communication with any other software that IDX currently supports.

Is there software available that can do this?

Yes. IDX has tested the Softing S5/S7 OPC Server as well as the Wonderware DasSIDirect Server, and the results that this test yielded were impressive when compared to the standard WinCC OPC server. A report of the findings is available and can be provided on request.

The shortfall with all existing products of its kind is the fact that when a full download is done from the PCS7 Engineering Station to the PLC, the DB Addresses change. The result of this is that tags now no longer point to the same piece of information in the PLC.

So, for example, before a download, the tag 440LIC104 at address (DB44, DW3) would point to a level indicator and after the download, if the address mappings are not updated, DB44, DW3 might now be the address of a furnace temperature, etc.

The new IDX Driver will detect this download and set the quality of the tags to BAD until the new addresses have been updated using IDX Unifig, after which the driver will continue transmitting the tag data.