A quick guide to getting access to the P+F advanced diagnostic module via RS485 and COM converter. In order to do this, you need an RS485 converter which can convert RS485 to either ethernet or USB.

I used a device from HMS (Anybus) called the Serial Server (AB7701). This device connects to RS232, 422 or 485 and makes the data available over ethernet to your computer using a virtual com port.

Instructions:

1. Connect the converter to the Diagnostic bus connection on the Pepperl & Fuchs fieldbus power hub.

2. Once you have the COM port available on your PC, check the comport number via “manage my computer”.

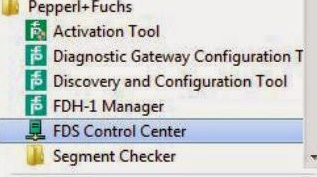

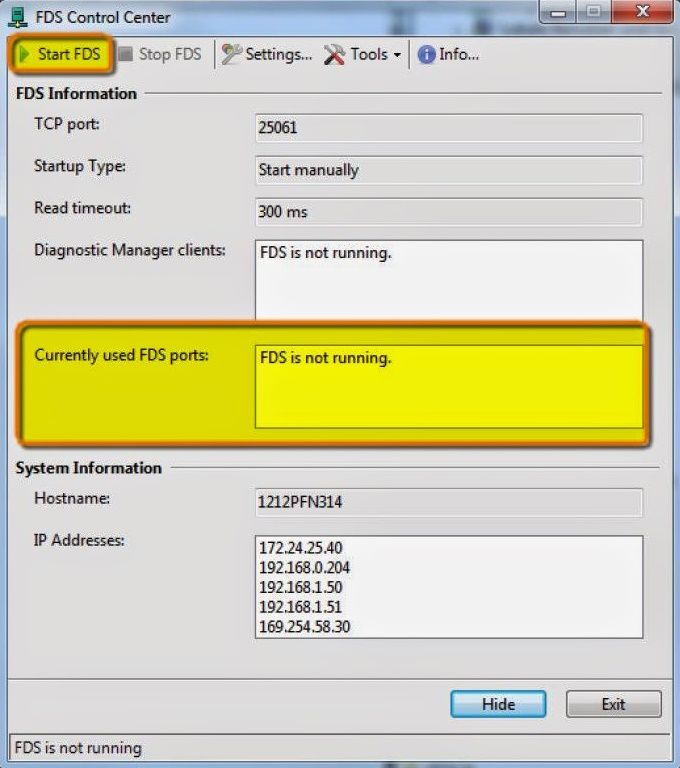

3. Make sure that the FieldConnexd Diagnostic server (FDS) is running. Go to “Windows button” > “All programs” > “Pepperl+Fuchs” and start the FDS control centre.

4. In case the FDS is not running click on “Start FDS” (in case it is running, there is nothing left to do here).

5. Click on “Hide”. To avoid this piece of software being forgotten in the future click on settings and choose “FDS settings” and “Start with Windows” (that’s the default configuration).

6. Start PACTware and create a new project in case it is not done automatically.

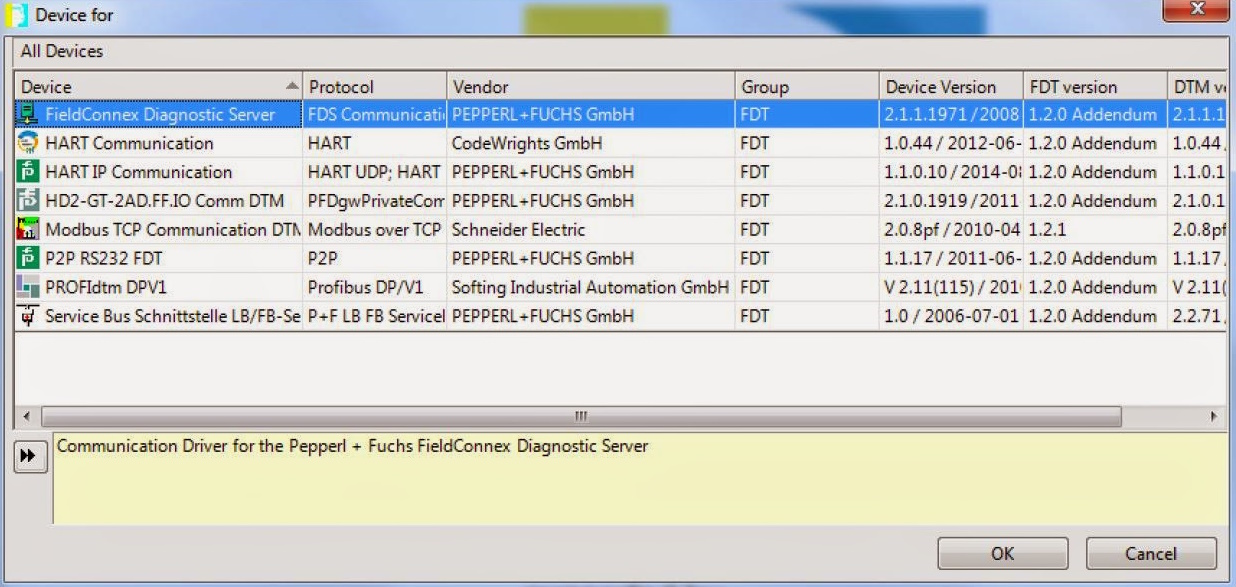

7. Add “FieldConnex Diagnostic Server” underneath the Host PC (e.g. right click onto the Host PC).

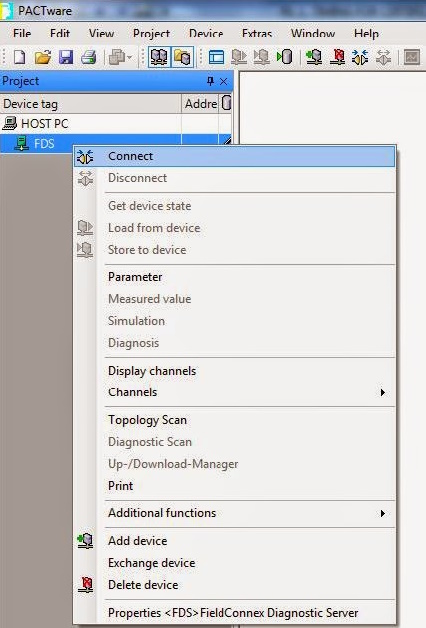

8. Do a right click on FDS in the project tree and choose “Connect”. The FDS should be displayed in bold letters.

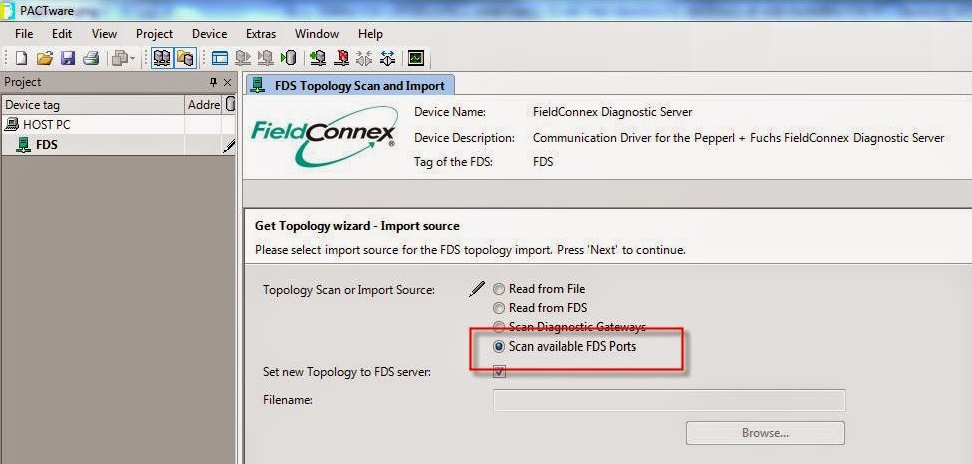

9. Choose in the following window “Scan available FDS Ports”.

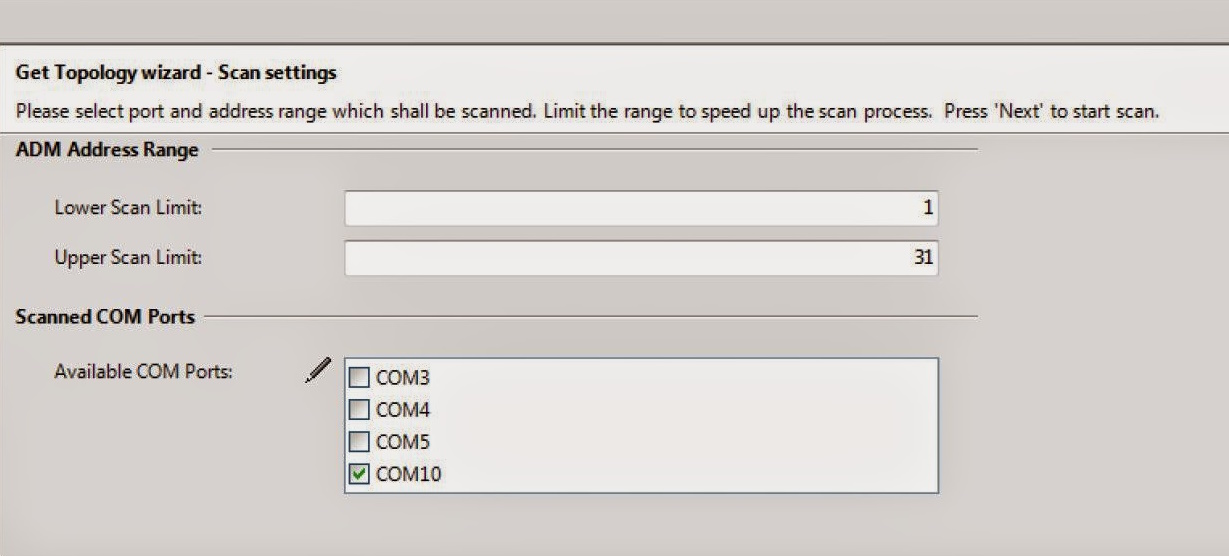

10. Choose in the following window the COM port of your virtual COM converter and click on “Next”.

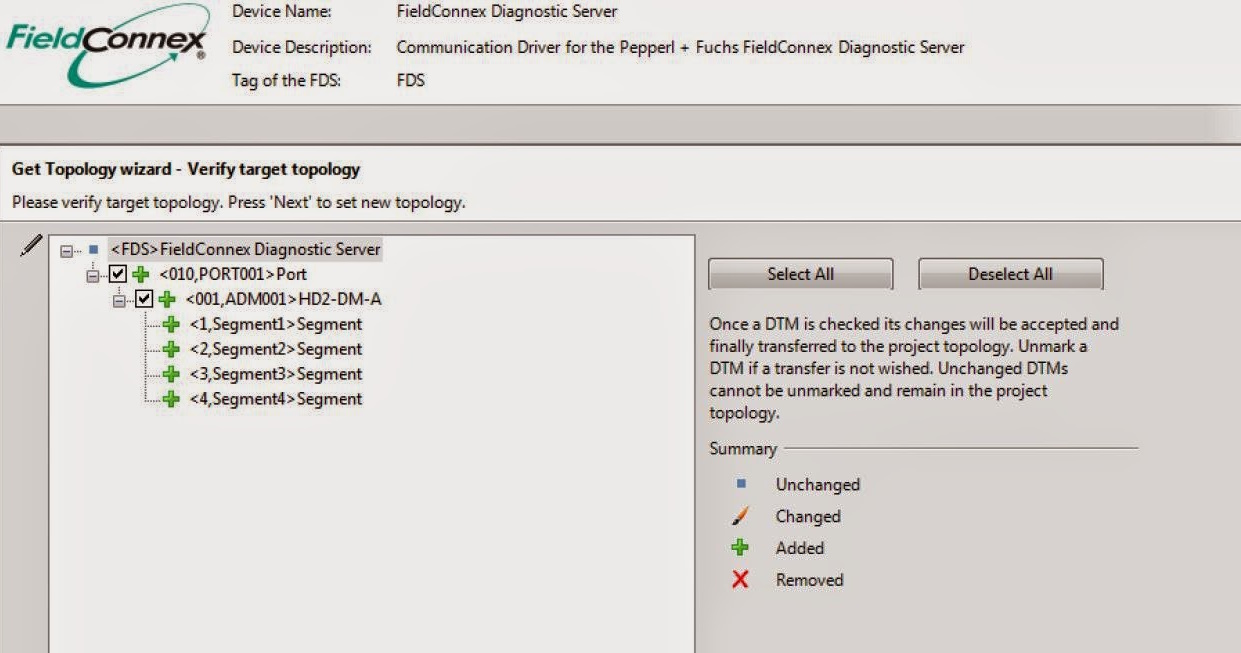

11. The DTM will scan the selected COM port for available P+F diagnostic modules. If the selection of the COM port and the wiring is OK the diagnostic module shall show up in the below window.

If it does not show up and the wiring is OK please check the ADM address setting on the left-hand side of the diagnostic module. There are 8 DIP switches for address setting and the address must be anything between 1 and 31 (address 0 is forbidden!) click on “Next”.

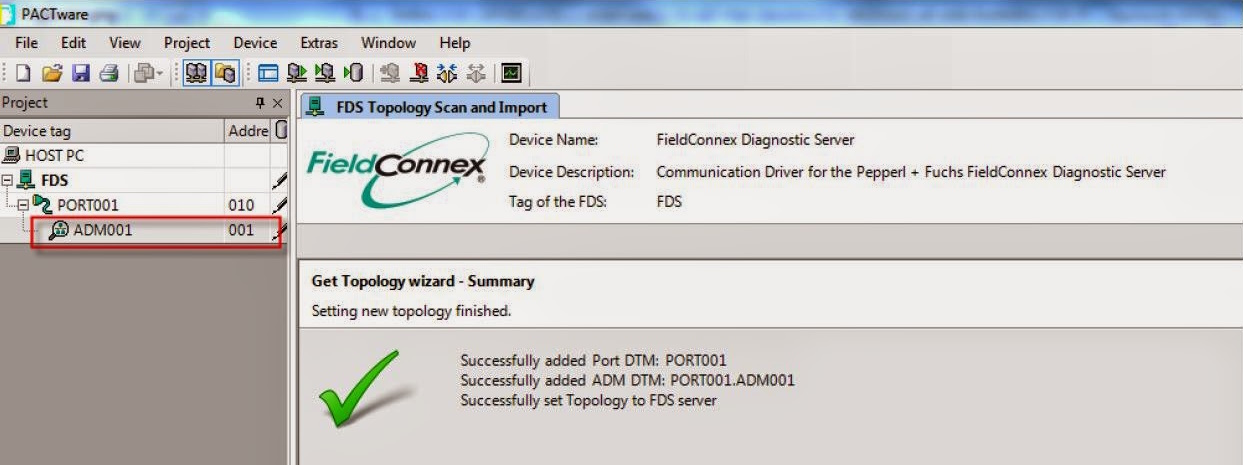

12. Now the ADM should show up in the project tree.

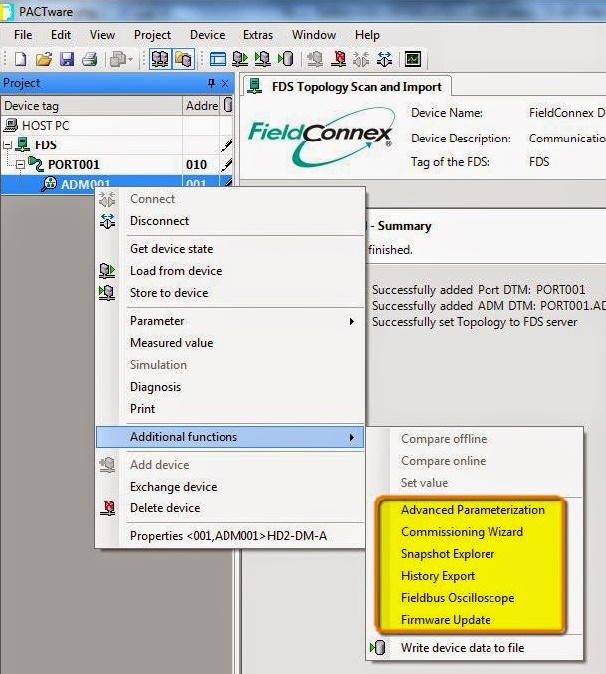

13. Establish a connection to the ADM. Go for “Device” > “Additional functions”. If in the highlighted area something is “greyed out” you don’t have an appropriate license.

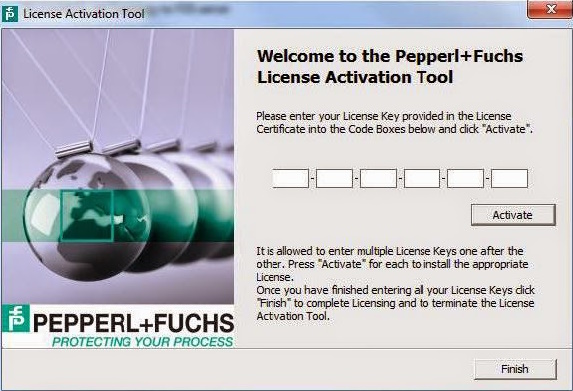

In that case, go for “All programs”> Pepperl+Fuchs> “Activation tool” Type in your license key, and click to activate.

After restarting the PACTware you will have access to all functionality.