Like any industrial network, PROFIBUS networks require consistent monitoring to ensure reliability, minimise downtime and prevent costly failures. Cyclic and ad hoc maintenance checks often fail to mitigate unexpected breakdowns.

Permanent monitoring solutions offer real-time insight into network health, helping one detect faults early and optimise performance; however, costs and complexity often deter companies from implementing these solutions.

In this article, we explore a cost-effective approach to PROFIBUS permanent monitoring, specifically high-level monitoring. This method serves as an excellent starting point for introducing permanent monitoring to your PROFIBUS networks. We will cover the differences between high-level and scope-level monitoring, highlight the advantages of each, and discuss typical deployments for high-level monitoring.

These insights will help you implement an efficient monitoring system tailored to your needs, which will enhance network stability and reduce maintenance costs.

PROFIBUS Permanent Monitoring

PROFIBUS permanent monitoring refers to the continuous diagnostics and real-time oversight of PROFIBUS networks. Permanent monitoring is crucial for maintaining optimal functionality and reliability in industrial automation systems.

Key aspects of permanent monitoring include:

- Continuous diagnostics: Permanent monitoring provides ongoing observation and analysis of the PROFIBUS network, helping to detect issues or anomalies in real-time.

- Proactive maintenance: Identifying potential problems early, allows for proactive maintenance and preventive action, reducing downtime and improving overall efficiency.

- Network health evaluation: Tracking parameters like signal quality, communication speed, and network load, offers insight into the health of the communication infrastructure.

- Data logging: This feature allows for long-term data collection and analysis to identify trends and recurring issues.

ComBricks: Effective Solution for PROFIBUS Permanent Monitoring

ComBricks is a modular system designed for the permanent monitoring of PROFIBUS installations. ComBricks offers two levels of monitoring: high-level monitoring and scope-level monitoring.

High-level monitoring provides a real-time overview of the entire network, including a complete device list and key PROFIBUS DP network statistics. It allows for quick identification of communication errors such as illegal messages, repeats, and sync issues, as well as performance trends. ComBricks can alert you to faults (e.g., lost devices, illegal messages) or potential issues (e.g., repeats, sync errors), helping prevent unexpected downtime.

In contrast, scope-level monitoring offers more in-depth diagnostics by providing detailed waveform analysis and device driver voltages. This helps pinpoint complex signal integrity issues, offering a deeper level of insight for troubleshooting.

With its remote access capabilities, ComBricks eliminates the need for on-site troubleshooting, making it a cost-effective and efficient solution for maintaining PROFIBUS network health centrally. Furthermore, troubleshooting can be performed without entering high-risk areas, such as hazardous industrial environments or accessing high-voltage panels in MCCs.

High-level monitoring provides a comprehensive live overview of your PROFIBUS network, offering essential statistics to ensure optimal performance.

It tracks key metrics such as:

- Lost devices

- Synchronisation errors

- Message repeats

- Diagnostic messages (sent and received)

- Illegal messages

- Slaves with parameter issues

- A network event log

- Email triggers and events

Practical High-Level Monitoring

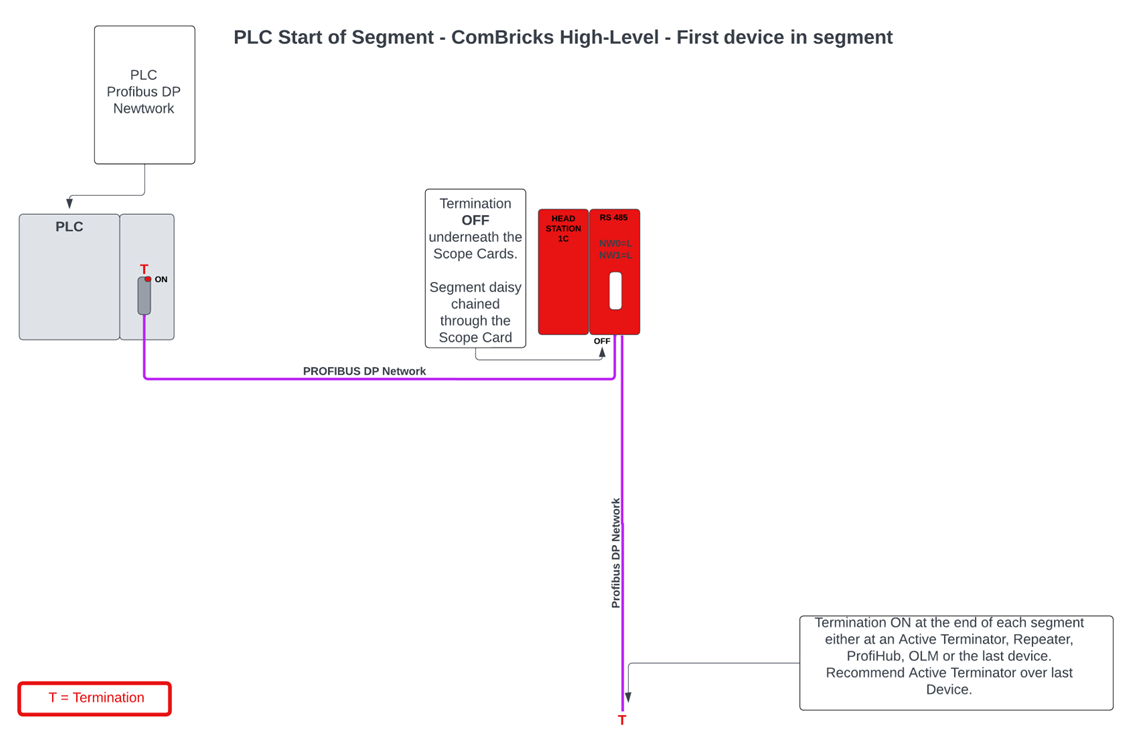

An Eco Monitoring Kit per PROFIBUS network is required if the PROFIBUS networks are physically separated in terms of distance from one another. The Eco Monitoring Kit consists of a 1B Head Station and one 1 Channel RS 485 Repeater unit. The 1B Head Station can monitor one PROFIBUS Network. The Eco Monitoring Kit is usually installed near the PLC. High-level monitoring offers a cost-effective implementation as it requires minimal hardware per network compared to scope-level monitoring.

Figure 1: ComBricks high-level monitoring: Eco Monitoring Kit

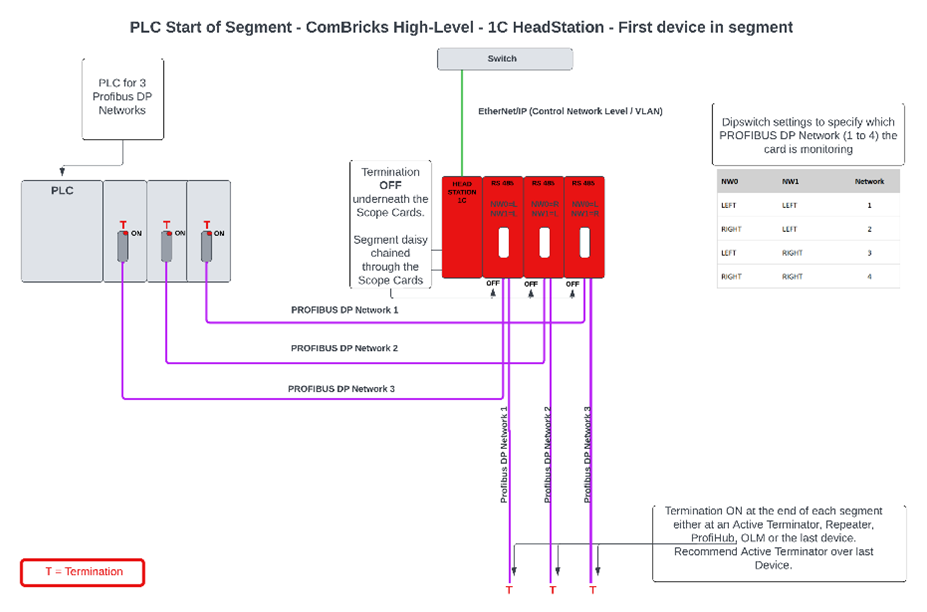

If multiple PROFIBUS networks are close to each other, for example, a PLC has multiple PROFIBUS cards, then a combination of a 1C Head Station and multiple (one per PROFIBUS Network) 1 Channel RS 485 Repeater units. This helps further minimise expenses when adopting ComBricks for high-level monitoring.

Figure 2: ComBricks high-level monitoring: 1C Head Station with multiple 1 Channel Repeaters

A key advantage of these above configurations is that even if the ComBricks system fails, the network will continue to function without disruption.

Integration of ProfiHub B5+R with High-Level Monitoring

When a plant already has a ProfiHub installed in its PROFIBUS Network, it can incorporate them into ComBricks high-level permanent monitoring.

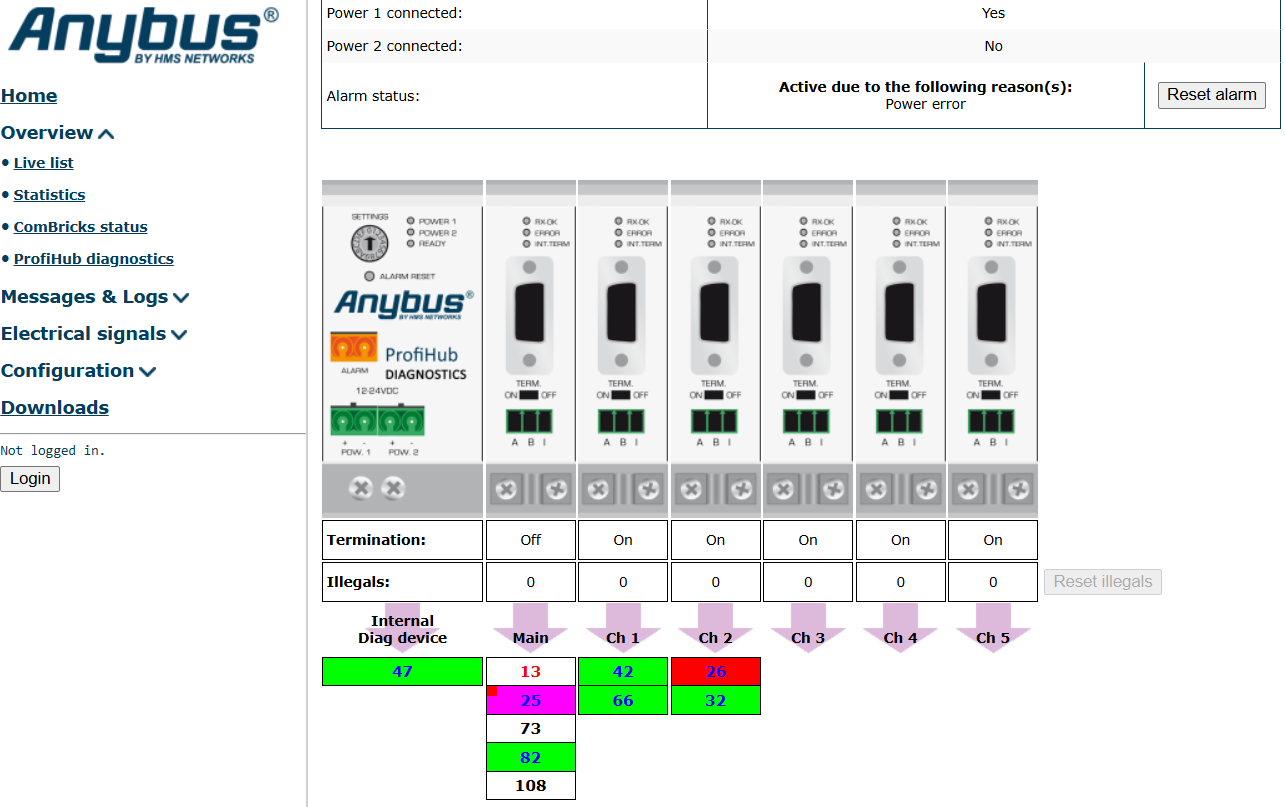

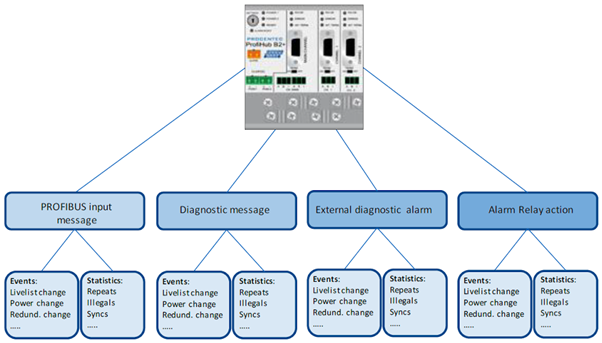

ComBricks allows you to view essential diagnostics for each channel. This information is accessible through the webpage of the connected ComBricks unit, where it is displayed in a clear and detailed format, as shown in Figure 3 below.

Once the ComBricks page is open, simply click on the Overview tab and then select ProfiHub Diagnostics. This will open the ProfiHub Interface, allowing you to view the connected devices on the network, along with the terminations and any illegals.

Figure 3: View of connected devices on the network

The displayed information includes the diagnostic device’s address, tag name, type, serial number, and firmware version. It also provides details on the ComBricks connection (network, module, and channel number), ProfiHub redundancy and power status, termination status, detected illegal messages, a live list of all channels, and the relay alarm status.

The diagnostic data is transmitted over PROFIBUS, allowing easy access through ProfiTrace software. This enables maintenance engineers to quickly pinpoint affected segments in the event of cable faults or instrument failures, significantly reducing downtime.

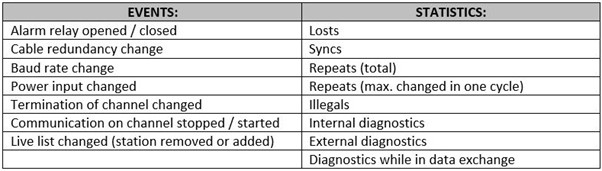

Figure 4: List of events and statistics

The events and statistics in the table above are continuously monitored and can be transmitted through various methods, ensuring that PLC/DCS users receive timely alerts about any network issues that may arise.

Figure 5: Diagnostic capabilities of the ProfiHub B2+R

In conclusion, the ComBricks high-level permanent monitoring solution offers a cost-effective and reliable way to enhance the performance and stability of PROFIBUS networks. By providing real-time diagnostics, ComBricks ensures early detection of issues, reducing downtime and maintenance costs. Whether integrated with existing systems or used for new installations, ComBricks empowers businesses to maintain a smooth, uninterrupted network operation while keeping costs under control.