However, while sharing this real-time data has become simpler, the management of the systems producing and consuming this data has not. Currently, if the real-time data elements, referred to as tags, are added or removed from the data producers, manual intervention is required to ensure those tags are added and removed from all the consuming systems to ensure configuration synchronisation between all systems.

Manual synchronisation is a tedious process when the systems involved are large, changes are frequent, and where small changes, such as a change in a tag’s maximum value attribute, may go undetected. In the process world, this problem is often seen when plant data is logged into a data historian.

In this case, it would be desirable that when changes are made to the source systems, such as the addition of data tags to the plant SCADA, for example, that these tags could automatically be set and created in the data historian to ensure the historian tag configuration remains synchronised with that of the SCADA.

IDX Tag Manager is an advanced, intelligent software solution designed to solve this problem. The principal behind IDX Tag Manager is to simplify this synchronisation and management process by:

- Providing purpose-built system components that can talk directly to the source and target systems involved.

- Detecting changes in configurations between source and target systems, and providing detailed information and/or summarised reports of those changes.

- Allowing changes to be selectively applied to target systems.

- Maintaining a history of any changes made in both the source and target systems.

Key benefits of IDX Tag Manager:

- Reduced time & effort to maintain target systems such as OSIsoft PI and Wonderware Data Historian.

- Systematic, repeatable approach with greatly increased precision.

- Provides a level of change control and auditability related to both Source (e.g. WinCC, Citect, Adroit, etc) and Target (e.g. OSIsoft PI, Wonderware Data Historian) Systems.

- Responsive local technical support.

- Free upgrades if on software support.

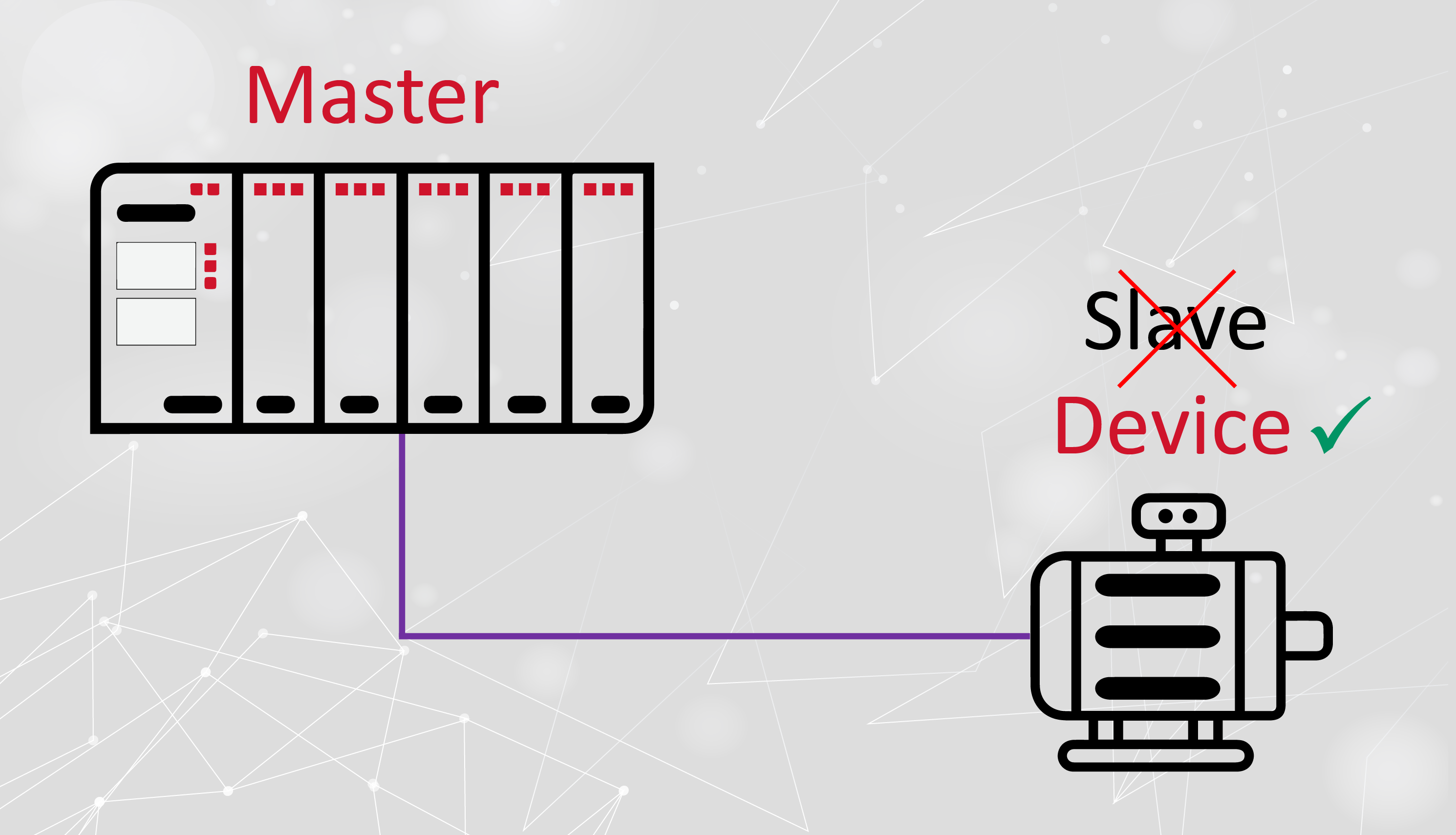

IDX Tag Manager contains components to communicate with commonly used systems such as Siemens WinCC, Microsoft SQL or custom format CSV files, while targets include Wonderware InSQL Historian, OSIsoft PI Historian, Microsoft SQL and custom format CSV files.

Once configured, Tag Manager allows for the continued synchronisation of source and target systems with greatly reduced time and effort but with increased precision, control and auditability.