The popularity of PROFINET is growing in South Africa and so too is the requirement for training. One interesting topic is the migration from PROFIBUS to PROFINET. It is not realistic to expect a site to one day stop its production (on PROFIBUS), buy new PROFINET equipment and start up production again.

The cost of the new equipment is a factor for sure, but the real cost is having a plant standing while an upgrade is happening. This topic is briefly covered in the Certified PROFINET Engineers Course run by the IDX Academy in Johannesburg under the Proxies Section. It is the only Certified PROFINET Course offered in South Africa and Africa as a whole. The course is accredited with ECSA and earns you 3 CPD points for attending.

Setting Up a PROFINET network

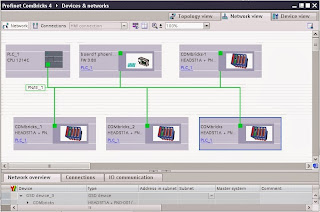

The Proxies Section of the course shows different ways of interfacing between different network protocols. One of the most common conversions would be converting between PROFIBUS and PROFINET, but it can also be a conversion between other fieldbuses such as MODBUS (See the blue Anybus Communicator in the picture above), ControlNet, DeviceNet, etc in which case one could easily use an Anybus X gateway from HMS. The Anybus Gateway can also come with a controller built-in, so there would for instance be no need for a PROFIBUS PLC on the PROFIBUS side.

The essentials for setting up and testing a PROFINET network including the PROFINET Cable Tester and Netilities from PROCENTEC

If the conversion is strictly between PROFIBUS and PROFINET, and there are PLCs on both networks, then the COMbricks PROFINET card and PROFIBUS device card can be used together as an alternative (COMbricks is shown to the bottom left of the picture above).

The PLC on the PROFIBUS side would write values to the COMbricks device card which can then be mapped to the PROFINET card. As far as the PROFINET Controller is concerned, it just sees the PROFIBUS values appearing as values on PROFINET and vice versa. You would just set the cards up as IO devices in TIA portal or similar software.

Of course, COMbricks then also offers its main feature which is permanent health monitoring of the network, but can also be extended to have some IO modules, so it may be a PROFINET IO device in its own right or even a PROFIBUS device IO block.