The difference between three 9’s (9.99%) and four 9’s (99.99%) availability on your PROFIBUS communications network could mean millions of Rands in lost production that directly affects your bottom line. Network rigidity and availability should be the core focus of any automation engineer who is tasked with maintaining a plant’s PROFIBUS communication system.

There are four main areas to focus on that will assist in improving your 9’s score on any given network:

1. Training

Fundamentally important, ensuring that all personnel who work with the network have the necessary training and know-how. Your local PROFIBUS / PROFINET Training Center will have a set of certified courses to ensure that all attendees are competent to handle installations and design scenarios. The following courses should be considered for PROFIBUS networks:

- Certified PROFIBUS Installers Course

Foundation PROFIBUS Training Course imparts knowledge of the PROFIBUS specifications, installation guidelines and necessary network components.

This course should be attended by EVERYONE who works on/with a PROFIBUS network (plant automation engineers, artisans, cable installers, system integrators & even management responsible for plant production and uptime).

- Certified PROFIBUS Engineers Course

More advanced PROFIBUS training that goes into detail on the PROFIBUS Specification, FDL analysis and advanced troubleshooting and maintenance procedures. PROFIBUS engineers are equipped to carry out network audits and conduct advanced analysis on the system.

Persons responsible for troubleshooting, design and maintenance of PROFIBUS networks would benefit substantially from this course.

- Certified PROFIBUS PA Engineers Course

Builds on top of the standard Certified PROFIBUS Engineers Course, giving advanced protocol-specific details on PROFIBUS Process Automation (PA). Being a very hands-on course, attendees will set up a PA segment and learn advanced design, analysis and troubleshooting techniques.

Persons responsible for troubleshooting, design and maintenance of PROFIBUS PA networks would benefit from this course.

- Certified PROFIBUS System Designer Course

Learn best practices for any industrial automation network, including PROFIBUS, Industrial Ethernet and lower-level protocols such as AS-I. Achieving high network availability is discussed in detail as well as a big focus on the necessary parts and components to achieve this.

Persons tasked with designing, implementing and maintaining industrial automation systems would benefit substantially from this course. This course is not just limited to the PROFIBUS protocol, as most industrial fieldbus and Ethernet systems work similarly.

2. Network Audit

A competent certified PROFIBUS engineer can evaluate each element of your installation, ensuring that all parts comply with the latest PROFIBUS installation requirements. On completion of the system evaluation, an audit report with all recommendations and fixes completed will be issued by the PCC (PROFIBUS / PROFINET Competence Center). Should the installation be found to fully meet the requirements, a report of compliance will be issued from the Competence Center.

A comprehensive network audit will give an insight into all the problem areas within your PROFIBUS system. A scheduled network audit is an extremely effective way of preventing breakdowns and downtime from occurring, unnecessarily costing the industry inordinate amounts each day. If you have a network audit carried out, this will ensure that your network gets back to the correct level of quality.

Some of the benefits that can be realised from an effective network audit include:

- A reduction in downtime and the associated lost production and costs

- Receiving details on network EMI interference, risk and corrective action

- Detailed reports issued with specific recommendations

- A proactive approach to ensuring your network is resilient against any interference

- Ensuring contractor installations meet PROFIBUS international guidelines

- Receiving detailed information on network design and expansion

You can contact your local PCC for a list of Certified Competent PROFIBUS & PROFINET engineers to assist you with a professional network audit.

3. Network Testing Tools

PROFIBUS is often referred to as a ‘hardware-based protocol’, thus it is crucial to have the necessary testing and assessment tools to assist you in fault finding, preventative maintenance and ensuring you have high network availability overall.

- Cable Tester

A cable tester will check the integrity and correctly implement the wiring of the cable before commissioning, ensuring that there are no wiring issues such as short circuits, open circuits, missing terminations, breaks in shield continuity, etc. - Bus Analyser

All users responsible for the maintenance and upkeep of an active PROFIBUS network should have access to a reliable and powerful bus analyser. A bus analyser is a hardware and software conglomerate that can read all telegrams being transmitted on the bus and generate key summary statistics of the bus operations. The analyser should also be able to measure and feedback on an electrical analysis of the bus signal utilizing an integrated oscilloscope.

Your testing tool should support the following requirements:

- Live list overview, showing the overall health of each PROFIBUS node

- Message recording and reporting functionality

- High-performance bus statistics with a summary view

- Advanced oscilloscope with differential and split signal view

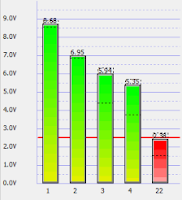

- Bar graph showing all driver voltages, including a varying high and low view

- Network topology detection and cable length measurement

- PROFIBUS controller simulator – allowing active network configuration by utilising its built-in GSD file database

The above specifications are based on the PROCENTEC PROFIBUS Troubleshooting Kit Ultra Pro.

4. Permanent Monitoring for preventative maintenance

Implementing an early warning detection system should be able to alert users to potential faults before they create a failure. Permanent monitoring solutions also monitor the network 24/7 and can provide a network engineer with the critical data and statistics needed to effectively correct any intermittent faults and faults occurring outside of maintenance shifts.

The entire infrastructure and architecture of your network should be able to feedback on error statistics and possible risks to higher-level notification systems.

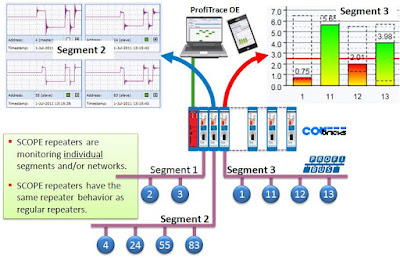

An example of this infrastructure may be a SCADA that receives network diagnostic information from lower-level infrastructure such as diagnostic repeaters.

For critical systems and processes, it is necessary to install an advanced permanent monitoring solution such as ComBricks. ComBricks is a modular, permanent monitoring solution for PROFIBUS networks. Each module can repeat to alternate channels to allow for full integration within the network architecture.

Each module has an integrated oscilloscope and ties into Procentec’s ProfiTrace framework to allow for in-depth signal, message and statistic analysis.

ComBricks transfers the data to the user through an onboard web interface which can be accessed through the plant’s existing Ethernet infrastructure, additionally, it can email users on certain risk thresholds being reached.