Tag management of real-time data systems can prove challenging. As an industrial IT company, we frequently come across problems where tags need to be migrated from one system to another or where tags need to be synchronised and maintained between systems including historians. Generally, this ends up being a manual process, often involving Excel and much diligence and patience on the maintainer’s behalf.

IDX Unifig was the first incarnation of a tool we designed to simplify the migration and management of tags between systems. The tool worked, but as with most first editions of software tools, we could see the need for improvement and refinement of the approach used. Thus Tag Manager was born and has become the keystone in the IDX 8 software suite. All other IDX 8 modules, such as Data Exchange, Alarms and Events and the Historian use Tag Manager to store and reference tags.

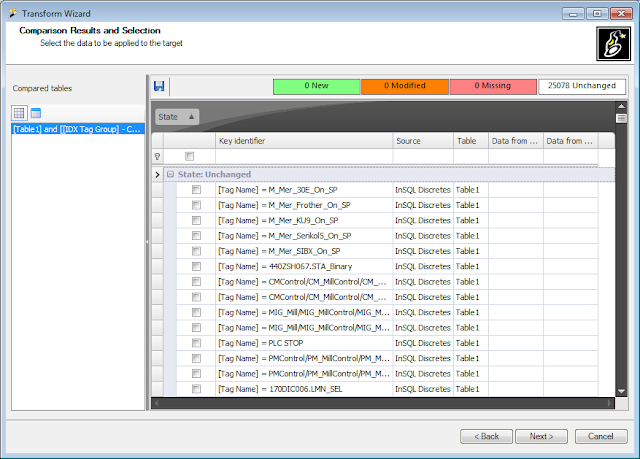

Tag Manager employs a plugin methodology that allows various sources and targets to be managed and synchronised. Currently, we mainly see the use of the Siemens WinCC and CSV sources, usually synchronising with WonderWare Historian (InSQL) and OSISoft PI Historian targets. The process of synchronisation is rule and wizard-driven and allows for a comprehensive comparison of tag data before synchronisation.

These rules allow data to be filtered, pivoted and “Regular-Expression-ed” into the required target format. That being said, there are still significant obstacles to overcome when dealing with certain sources in particular, which play a critical role in determining the overall simplicity of tag synchronisation.

The comparison result we like to see – no changes.

For example, a common scenario we have is to synchronise tags in WinCC with tags in PI Historian. It must be highlighted that the ease of synchronisation is markedly affected by the rigorous adoption of a standardised naming convention for tags. Without this, you can quickly become bogged down in naming exceptions – while still do-able, usually means more initial rule setup and configuration time. Also, certain systems complicate matters further in that they use Tag names as the system’s unique tag identifier (e.g. WinCC).

This is a bad idea simply because it in no way facilitates the ability to rename tags in the source without destroying the possibility of avoiding additional manual intervention of synchronisation between other systems. WinCC does have a tag identifier value associated with a Tag, but this identifier is not stored in some kind of central configuration repository – it changes when a full PLC download occurs which naturally breaks fully automated synchronisation.

In such cases, additional care must be taken to synchronise configurations. It is mainly because of cases such as the above that Tag Manager is not yet a fully automatic, click-once-and-forget affair (a request we have received more than once – we are looking into it is all I can say at the moment).

Tag Manager is used on an ongoing basis for tag synchronisation, usually in a WinCC to Wonderware Historian or more frequently, OSIsoft PI Historian configuration across the various Platinum producer sites in South Africa.