IDX attended a PROFIBUS call out for a gold mine situated in Welkom. The client reported issues such as “loss of communication and network trips”.

Using the PROCENTEC Mercury Pro Kit (A complete diagnostics tool for troubleshooting PROFIBUS and Industrial Ethernet Networks) we were able to identify the underlying issue as a short between the B-core (red wire) and the PROFIBUS cable shield.

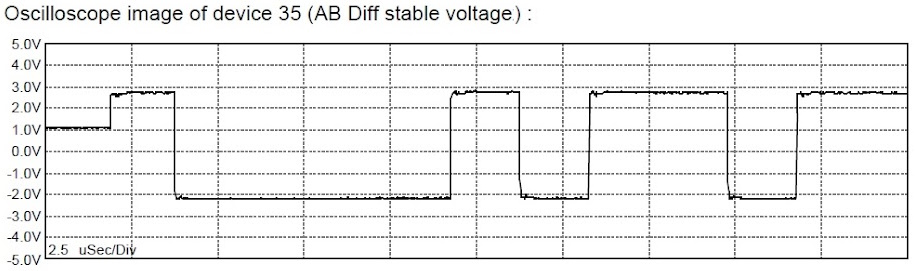

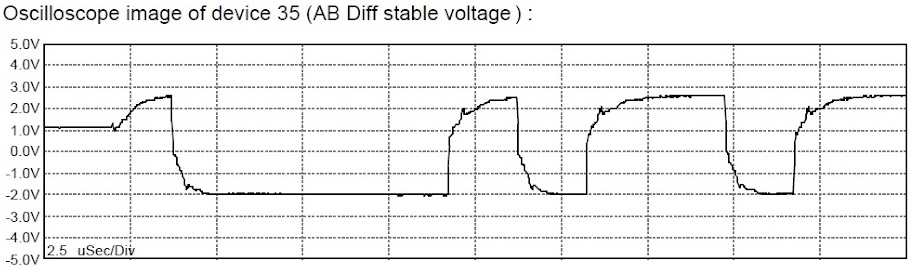

The short in the PROFIBUS cable meant that the differential signal was significantly lower in amplitude and therefore more susceptible to earthing faults and EMI injections on the bus.

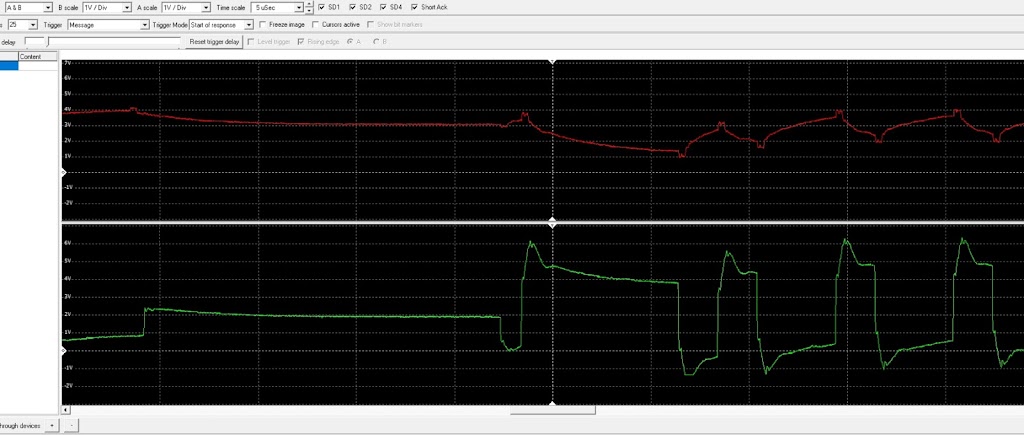

PROFIBUS makes use of a balanced signal. This means that the signals transmitted on the A and B channels have similar voltage levels, however, they have opposite polarities. The differential signal is calculated as B – ( – A).

When a short occurs on the PROFIBUS cable between either of these cores and the PROFIBUS cable shield, the shorted core will produce a flat line and the resultant differential signal will effectively be halved.

This balanced communication method also helps to combat any noise that may be picked up on the network. The assumption is that any interference injected on the bus will be picked up on both the A and B channels which, when combined, will result in a clean differential signal.

PROFIBUS network was still running on a single core, the interference injected onto the network when certain machines or drives were started, was enough to cause communication issues and intermittent network trips.

An oscilloscope that can display the individual signals of each of the cores is necessary to effectively identify a “short to shield”. Both the Osiris software (Mercury Pro Kit) and the ProfiTrace software (PROFIBUS Troubleshooting Tool Kit) have this functionality built in.

By enabling the terminating resistors at certain points on the segment, we could pinpoint the exact location of the fault and replace the faulty cable. After limited downtime for the repair work to take place, we had the network up and running. Oscilloscope measurements taken after the fault had been rectified confirmed a healthy PROFIBUS signal on both A & B channels and in turn, a much more robust differential signal. No network trips have since been reported.

Maintaining your existing connections, in this case, maintaining a healthy PROFIBUS network is the responsibility of the on-site technical team. As with anything, the necessary knowledge and the right tools for the job are required to ensure that your production is not affected.