Is network downtime getting you down? Introducing PROCENTEC’s range of ProfiHubs, now with new diagnostic capabilities!

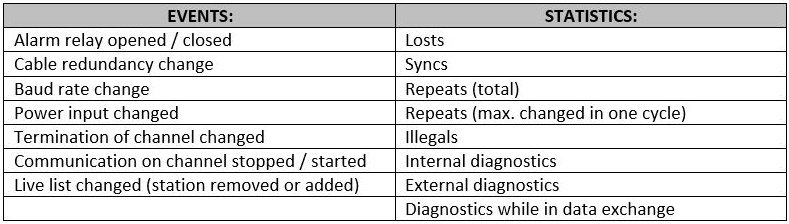

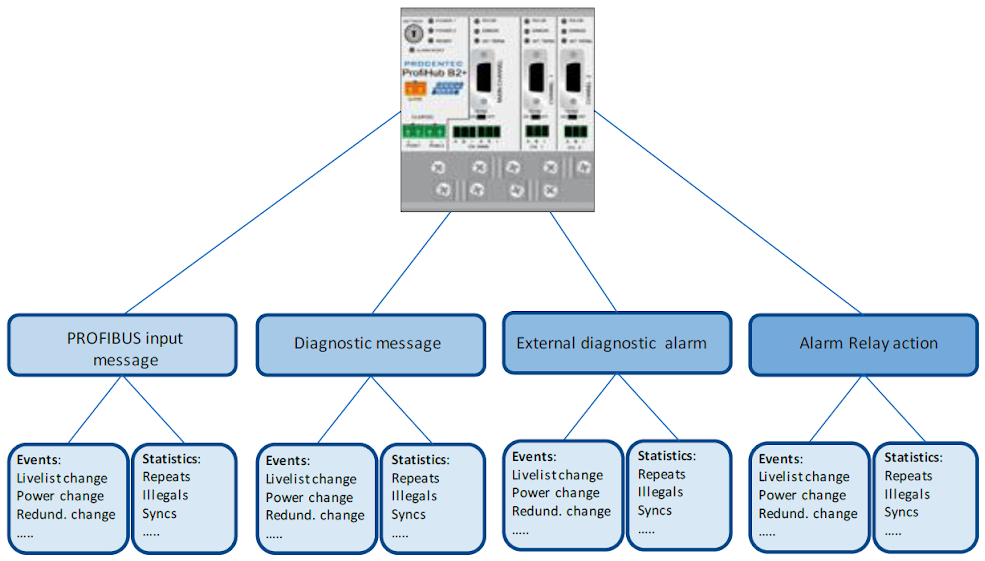

The diagnostic ProfiHub is a versatile statistics/diagnostics logger that can be used to keep track of the overall network health and inform either the PLC or DCS of any network failures. These network failures could be in the form of repeated messages, illegal messages, missing ProfiHub terminations, live list changes or power supply problems. Audible or visible feedback can also be achieved by switching the integrated alarm relay of the ProfiHub.

All ProfiHubs are now shipped with this functionality available as standard. Existing ProfiHub owners will soon be able to purchase upgrade packages to enable the diagnostic capabilities via a firmware update. The diagnostic capabilities are available for the B2+R, B5+R, D1, B2FO2, & B4FO2 and these hubs are fully compatible with PROCENTEC ComBricks providing you with a permanent monitoring solution that lets you troubleshoot your network down to the last segment.

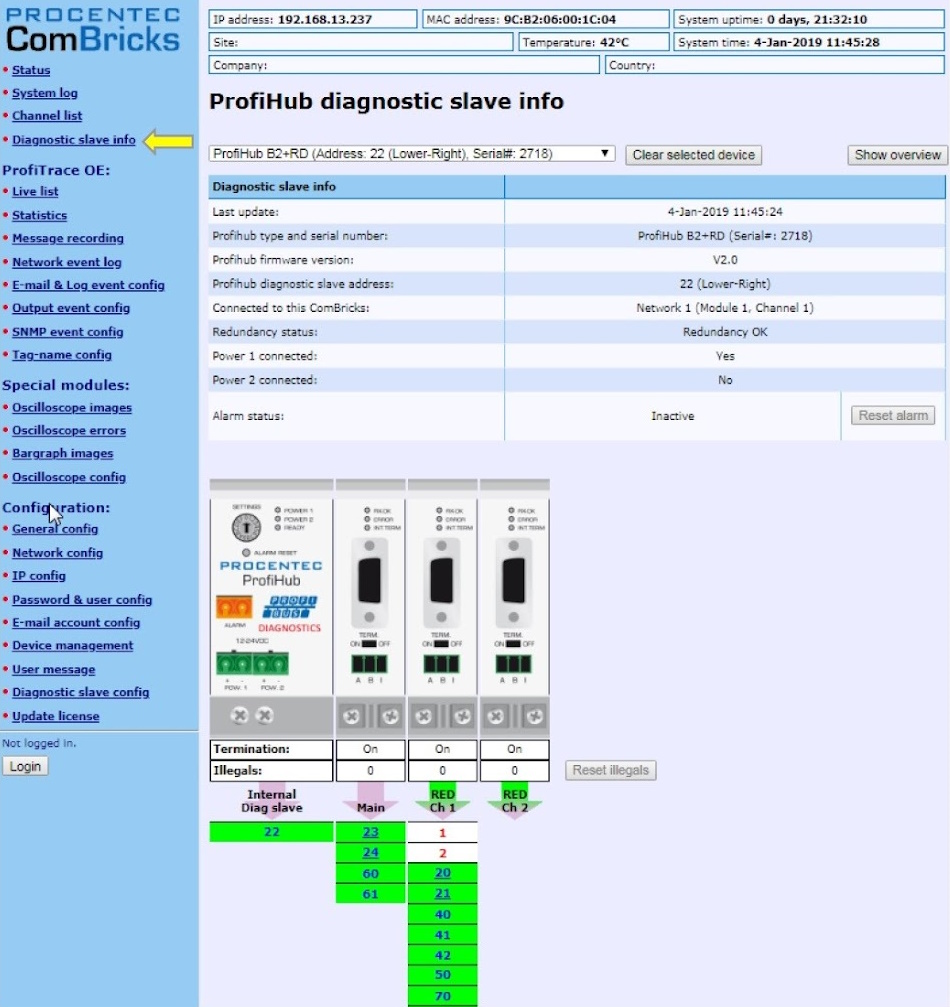

You can use ComBricks to display the most important diagnostics of every channel. This information can be accessed through the webpage of the connected ComBricks unit and the information is displayed as follows:

The information displayed includes the address, tag name, type, serial number and firmware version of the diagnostic device, the connection (network, module and channel number) of the ComBricks, the redundancy and power status of the ProfiHub, the termination status, illegals and a live list of all channels and the alarm status (of the relay).

The diagnostic data is sent over PROFIBUS so the information can be easily read using the ProfiTrace software. Maintenance engineers can immediately identify the affected segment in the case of cable faults or instrument failure, which drastically decreases downtime.

The events and statistics in the table above are continuously monitored and can be transferred in the following ways so that a PLC / DCS user can be warned of any network issues that may arise.

Visit the demo environment at http://combricks.idx.co.za/ to see how the diagnostic ProfiHubs can be integrated with ComBricks.