Sometimes the intermittent and unexplained failures of a PROFIBUS network can only be explained as one thing: “My system has caught the PROFIBUS virus!”

This is how it must appear to someone who doesn’t have the right tools to analyse and monitor what is going on with the network. It is important to realise that an error, on a PROFIBUS network, does not necessarily mean a system failure. A classic statement that our PROFIBUS Engineers receive on arriving to troubleshoot a PROFIBUS network is: “But it was running fine for all these years – why does it fail suddenly now?”

To answer that question, you can think of it this way: does a person die the moment they have a cough? Maybe a bit of a drastic analogy, but the answer is of course not! The person will go to the doctor for a checkup, who uses his tools to listen and see what is going on. If his symptoms are left unattended, then the outlook might not be so great. PROFIBUS is robust though! You need to violate installation rules, quite seriously, for it to fail.

Just like a person goes for a health checkup, so too does a PROFIBUS network need a health checkup!

PROFIBUS users have tools available that can help them do a “checkup” on their network. ProfiTrace is just such a tool – it tells us if there are any illegal/corrupted messages on the network and if there are malformed signals with its ScopeWare and can even generate reports based on this. Sometimes though, the errors (which are not failures) are very intermittent and happen when the test tools are not connected! You also want to know the moment an error happens – before it accumulates to cause a system failure or plant trip.

Imagine we could have a doctor permanently connected to us and tell us tell us something is wrong the moment it happens! This isn’t possible, but it is possible for PROFIBUS! COMbricks can be connected to your PROFIBUS network and is listening for any errors before they cause a failure. The user can investigate the cause of the error and take action. Preventative maintenance is kind of like taking a vaccine – it prevents you from getting sick.

A local steel-cutting factory in South Africa sees the value of this. They are using COMbricks to monitor their line for any errors which may lead to failures. The following issues have all been detected on this line using a combination of ProfiTrace and COMbricks:

- Termination errors

- Faulty devices

- Corroded PROFIBUS connectors (bad earthing)

- Bus cable to close to high voltage lines

They realise that being able to prevent failures is well worth the outlay of the initial hardware cost. It makes sense to buy equipment that will pay for itself. For a site such as this one, preventing a single plant trip is worth much more than the cost of this extraordinary piece of hardware.

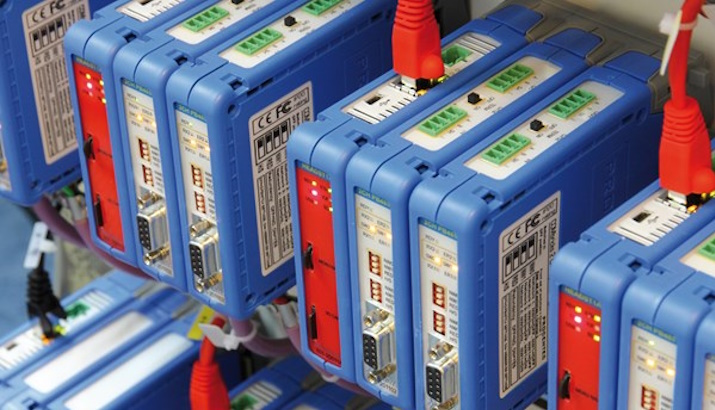

The above image shows the COMbricks headstation getting a firmware update with the latest features before being commissioned. Such a tiny device with a huge responsibility!

In the picture below COMbricks is not only monitoring the health of the PROFIBUS network but is also acting as a PROFIBUS repeater.