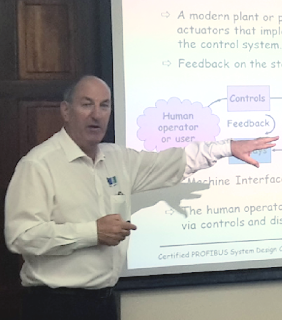

IDX will again be hosting Andy Verwer from the UK to present the Three-Term or PID (Proportional Integral Derivative) basic course in Johannesburg, South Africa. The training is aimed at technicians, engineers and programmers who are involved in the operation, implementation and tuning of feedback controllers in a wide variety of applications and industries. Many different aspects of feedback control systems are covered so that the training will benefit a wide range of needs.

For example, if you need to:

- Apply quantitative feedback control to real processes and machinery

- Improve the performance or tune controllers in their plant

- Implement three-term controllers in their programmable control systems (PLCs and DCS systems)

- Identify problems and the causes of poor control performance

The training will run over two days and is for those who have little or no previous experience with feedback control. This module takes the trainee up to the stage where they can tune a simple feedback control system and identify the basic reasons for poor control performance.

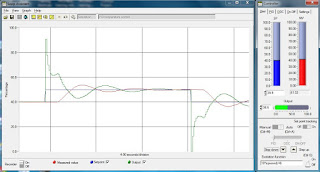

There will be a practical component which is delivered in a hands-on manner using a combination of simulation software and real processes. The material in the basic and advanced courses is delivered in a manufacturer-independent way.

The basic PID control course introduces control system terminology and technology and introduces three-term (PID) control using a practical, hands-on approach. The basic PID course teaches how the controller terms operate and interact and how to use simple but practical techniques to select and adjust a controller for a range of applications. The training also covers the various causes of poor performance, which are often not concerned with controller tuning.

The content will include:

- Feedback control system architecture and terminology. Features of real controllers. Typical control systems for level, pressure, temperature and flow control. Hands-on practical operation of a control system.

- Common control actions. Simple process dynamics. Common problems associated with feedback control. Hands-on simulation exercises System load performance, reset windup. Control performance measures. Modelling of process dynamics and nonlinearities. Control valve characteristics and problems.

- Simple controller tuning methods. Practical tuning exercises for flow, level and pressure control.

The course cost will be R8 550 including VAT and will be held at the IDX office at 1 Weaver Street, Fourways from the 29th to the 30th of May 2017. Lunch will be included.

Seats are limited and booking is essential. Please send your booking requests to academy@idx.co.za.

We look forward to seeing you there!