The KICC Expo Centre was very heavily guarded, every attendee entering, went through rigorous physical and identity checks. This took me somewhat by surprise, however, I did humbly abide as it made everyone feel a lot more comfortable for the safety of the venue and all participants attending.

On Thursday morning the excitement kicked off quite abruptly as a hoard of fascinated delegates started sweeping from stand to stand. I had the welcoming opportunity of picking off every person who got within grabbing reach of the IDX stand to spread our offerings, and marketing rather enthusiastically.

I found every visitor and delegate was humble and welcomed the influx of information each exhibitor had to throw at them. The most encouraging was how excited and passionate each attendee was to learn something new and identify new opportunities.

IDX exhibited the following technologies at EAPIC:

- Netbiter enables you to remotely monitor and control your field equipment – anytime, anyplace.

- Monitor energy consumption, fuel levels, battery status etc.

- Start or stop equipment remotely.

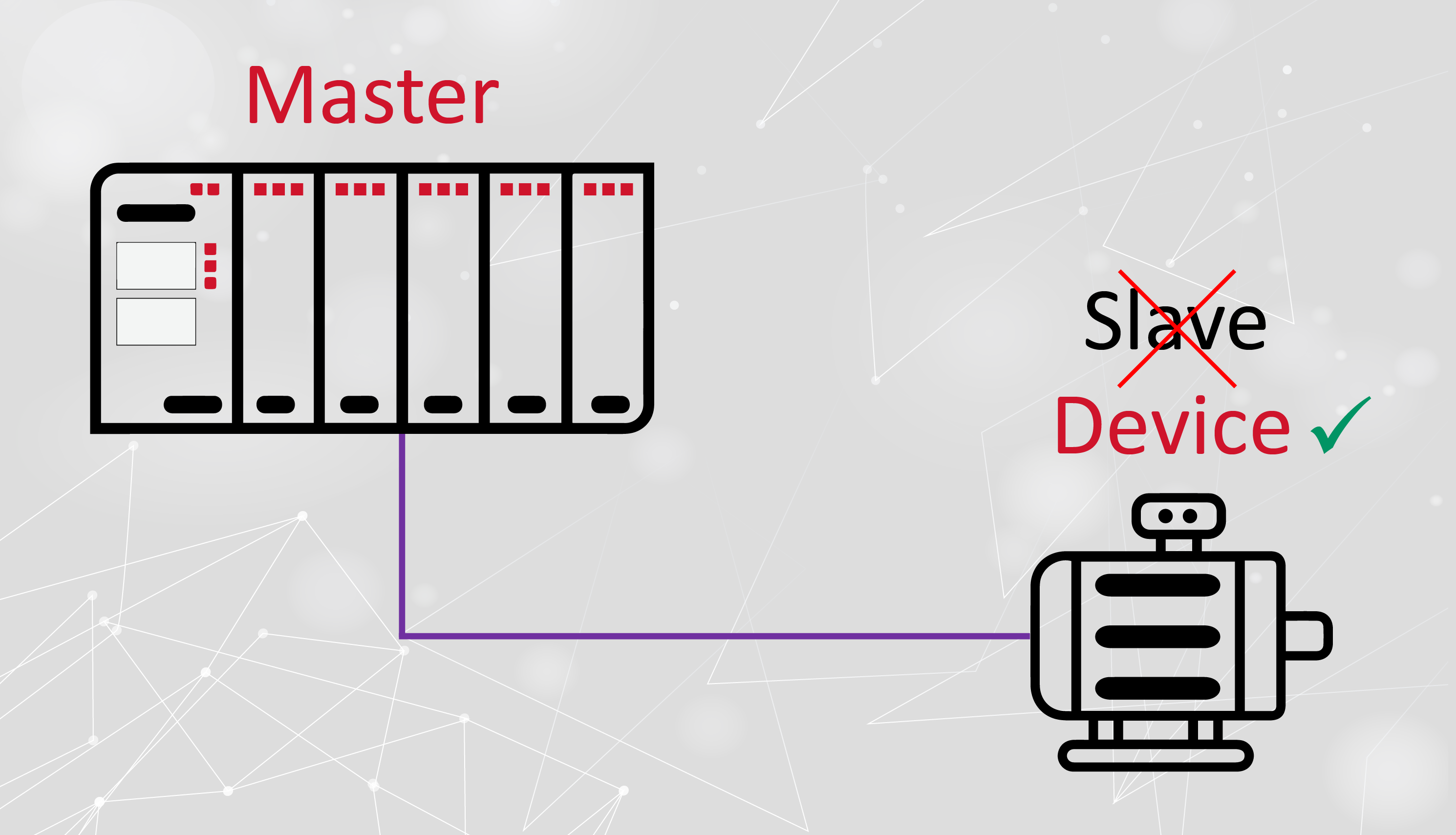

- Configure machines and PLCs remotely.

- The IDX Nexus is a family of modular hardware and software components that allow flexible data monitoring and control solutions to be applied to machines in extremely harsh environments. When used in combination with the IDX Suite, fleet management and other real-time optimization strategies for distributed assets can be cost-effectively realised.

- Solving smart grid communication challenges: The LABLINE SG gateway family targets Demand Response (networking of industrial electric loads) and Virtual Power Plants (networking of energy resources like biogas plants or combined head and power units) applications.

The Labline SG devices support both protocols utilised in the energy sector as well as supported protocols of electric equipment in the field, this can be interfaced with any industrial fieldbus/Ethernet network. The logic of the device can be programmed on its embedded soft PLC.

Overall the convention was bursting with lively business, and enthusiasm and was of a high calibre. I was fortunate enough to liaise with the most intelligent and fascinating people.

I would like to give a big congratulations to all the other exhibitors in the South African Pavilion, you all did a sterling job and the energy was on an unfathomable level, and a huge shout out to the South African Electrotechnical Export Council, without non-of this week’s festivities would be possible.