Data Exchange has been the core of the IDX suite since its first inception in 1995. Data Exchange allows real-time tag data to be shared between various, usually incompatible, systems with IDX being the intermediary that converts the data between the systems. Up to IDX 7, IDX was exclusively a Data Exchange engine with a reliable industry track record. IDX 7 still exists today and provides the bulk to the Data Exchange requirements to service our clients’ needs. This includes special connectors such as the Gensym G2 Expert Sytem bridge, as well as more common OPC DA, MODBUS, and OPC DA tunnelling via TCP.

IDX 8 introduces its implementation of the Data Exchange engine. The intention is to mirror the functionality of common IDX 7 connectors, such as the OPC DA client, in native IDX 8 connectors to provide general data exchangeability to service functionality such as Alerting (more below). However, soon, the IDX 7 runtime will become a “proxy” data exchange engine of the IDX 8 framework, so that all the existing IDX 7 connectors can be configured and used from within IDX 8 without the need for the separate IDX 7 configuration tool and database.

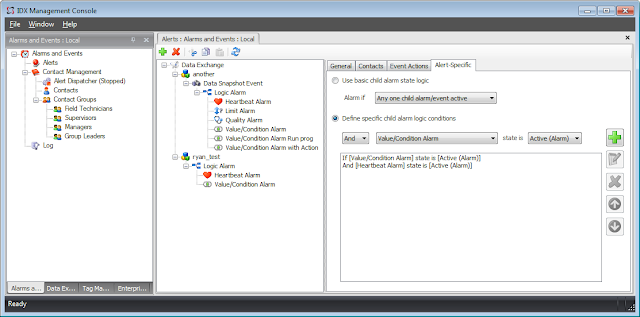

One of the more exciting new aspects of IDX 8 Data Exchange is that it couples to the IDX 8 Alarms and Events modules, which allows users to set up SMS and/or Email notifications based on configurable, hierarchical alarm logic. The standard alarm types are available, such as value, limit and heartbeat alarms. Two alarm types in particular provide additional useful functionality. The Logic alarm is used to aggregate alarms up the logic tree and this allows one to set up alarm configurations that do not send emails and SMS unnecessarily. Customised logic can be set up so that the logic alarm only enters the alarm state if its child alarm states match those specified.

Configuring a Logic alarm that analyses the state of a Heartbeat and Value/Condition alarm. The Snapshot alarm allows you to generate a value snapshot of one or more Alarm Event items, such as Data Exchange tags, at the time the alarm is triggered in the alarm tree. You can format the snapshot message to your requirements with custom text so that the data snapshot is presented as required in an Email or SMS message.

At the time an alarm occurs, there is also the option to perform an action, which includes running a program, controlling a Windows service or writing a value into an Alarm Element such as a Data Exchange tag. We have used the service control action in many projects where alarms are set to monitor the health of other real-time data interfaces that happen to stop working once in a while. The Alarm action allows us to restart the interface services to get the data moving again without any user intervention.

Alarms can also be set up with acknowledgement escalation where, if an alarm is not acknowledged by any contacts in a group, the alarm is escalated to the next group. All alarms alarm notifications and acknowledgements are logged, providing a useful event audit trail.