On 11 September 2013, IDX attended a “bullring” meeting at the Nigeria Inward Mission Event hosted by the South African Electrotechnical Export Council (SAEEC). The meeting was held at the Johannesburg Country Club. At this meeting, members of SAEEC could host a table demonstrating to the Nigerian Delegates their core offerings – The IDX focus was on Remote Monitoring Solutions for Africa.

The delegates included those from presidential roles, ministry and government, and national and federal power agencies – the main focus was on power and energy. In a bullring meeting, the delegates have about 25 minutes at each table before they move on to the next table.

David Bean from IDX talks about remote monitoring for Africa at SAEEC Nigeria Inward Mission.

In each meeting, IDX would engage with the delegate to determine what sort of business they were in and what their various challenges were. Some themes that emerged included:

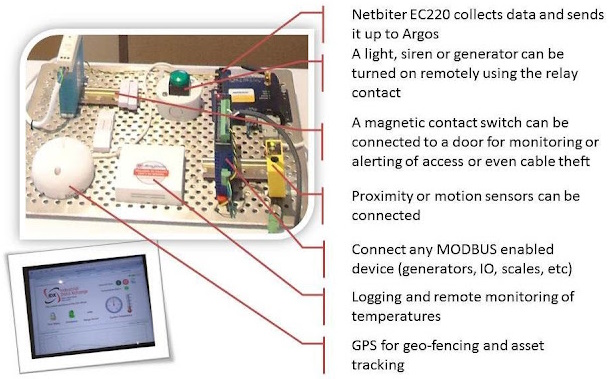

- Remote monitoring of generators

- Remote monitoring and control of agriculture systems

- Cable theft alerting systems

- Diesel theft alerting systems

- Training (in PROFIBUS and MODBUS for example)

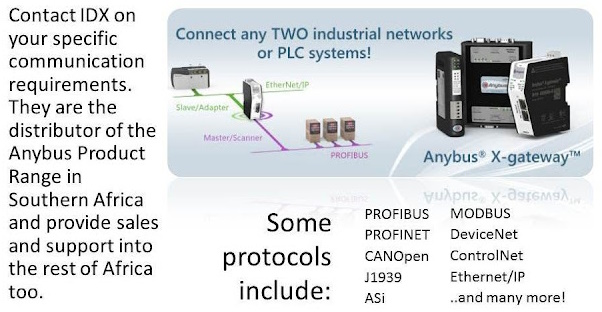

- Translating between protocols

- Permanent monitoring systems for PROFIBUS and MODBUS networks

IDX demonstrated the possibilities of addressing these challenges these with some of the devices on their table.

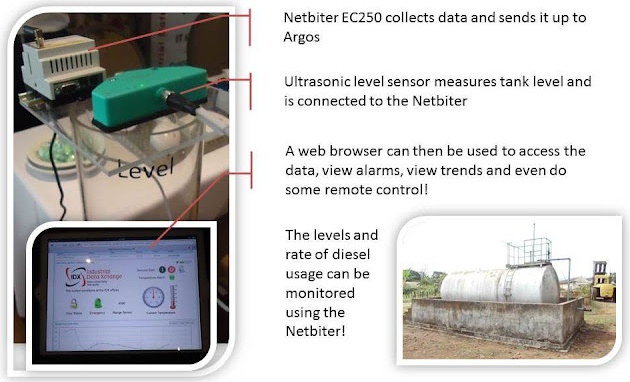

Tank level monitoring for agriculture, generators, remote base station tanks and alerting of diesel theft.

Substation access monitoring, remote control of generators and cable theft alerting.

Translation between protocols – getting disparate systems to talk to each other.

Permanent remote monitoring of PROFIBUS networks

PROFIBUS is an industrial communications protocol used in factories and plants and connects all the conveyers, pumps, actuators, motors, etc. to the control room. If the health of the PROFIBUS network is compromised, production is compromised.

COMbricks from PROCENTEC will alert you on any changes in the network health and allow an expert to remotely access the health statistics of the PROFIBUS network so that they can advise on any corrective action before production is affected. It also has modules for fibre optics, PROFINET, PROFIBUS PA, Device IO and repeaters so it becomes an integral part of your network infrastructure while still monitoring it.

Expert Fieldbus Training

The IDX Academy provides training in various fieldbuses like ASi and MODBUS. It runs the only PROFIBUSCompetence Centre (PCC) in Africa where you can receive internationally certified PROFIBUS and PROFINET training.

In Conclusion

There are often too few skilled people at remote sites so technology needs to be leveraged to enable and a small pool of skilled engineers to be able to remotely access and support sites.

With some training, organisations can be empowered to monitor, track and be alerted on their asset states so that they can react effectively to these events.