The Netbiter® device along with its ArgosTM web service technology is becoming increasingly popular in South Africa. Already it has been implemented at numerous sites for monitoring water treatment rigs, heavy machinery and other metering equipment.

Very quickly the user can connect some IO or MODBUS devices to the Netbiter® and view and control these values through a web-based graphical dashboard. The user can see the current state of their system, view historical data and even receive alarms from their system. No programming is required! This is all done through the secure Netbiter ArgosTM Web Interface.

It is a very powerful way to monitor a MODBUS device over the Internet and by using the IO Extender cards, the user can switch relays and monitor additional digital and analogue IO through a web browser. Netbiter® is truly a complete package that provides one of the most flexible solutions to monitor control devices over The Internet.

Furthermore, as of March 2012, HMS announced that customers will no longer have to pay any subscription fees to access Netbiter ArgosTM. All you need is the hardware and you’ll be on your way! This means that customers will have access to extended reporting capabilities, improved data logging resolution, the addition of more users to a system, multiple adding of devices to a single account and among other things, have access to the GPS services and the Netbiter ArgosTM Web services.

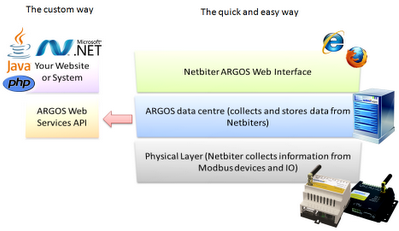

One of the lesser-known features of the Netbiter® is the power of the ArgosTM web services API. The API is based on SOAP and WSDL and provides a means for a programmer to access the ArgosTM Data Centre and retrieve alarms and historical data. Soon the ability to read the current Netbiter® values will be released also. Since the API is programming language independent, developers using .Net, PHP, Python or Java will be able to make use of this service.

The real benefit of this is that the customer can pull information into their website or system and create views and reports that are specific to their needs. IDX has already made use of this service by using the .Net Framework and specifically the C# language.

Feel free to contact them if you’d like more information on any of the Netbiter® products or if you would like to make use of these services. We would be glad to discuss your requirements and suggest a solution for you.