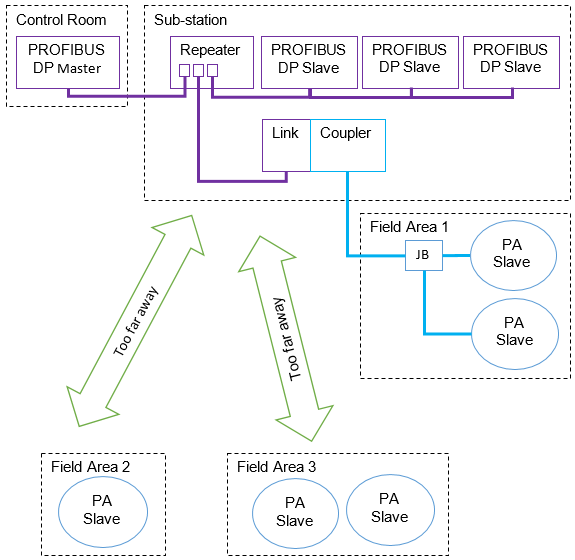

We’ve been receiving numerous requests for converting PROFIBUS PA to fibre optics lately. I believe that really what the request is is that there is an existing PROFIBUS DP Controller with DP (and possibly existing PA) infrastructure and the requirement is to add some PA devices that are out in the field.

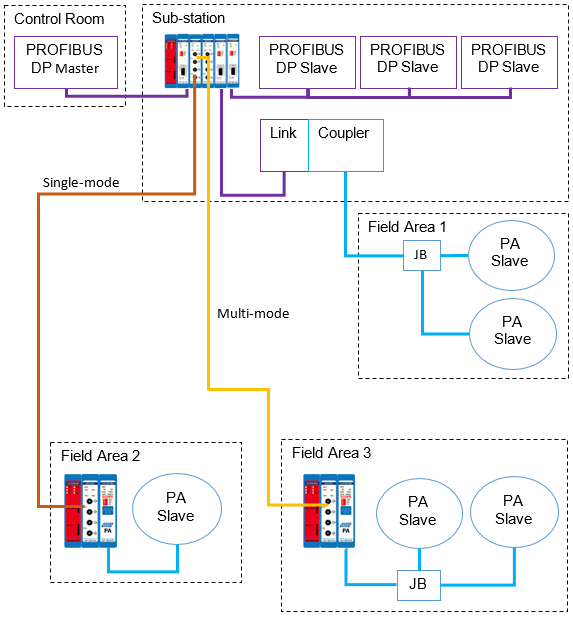

PROCENTEC have a range of COMbricks modules that can meet almost any type of network configuration. In this article, we’ll investigate some of the configuration options and which components should be used in each configuration. Your network layout might look something like the picture below:

Being able to run fibre to these field areas has the following advantages:

- Fibre can be run over longer distances, and PROCENTEC offers up to 30km of single-mode fibre. Typically, 2km on multi-mode.

- Fibre can run through areas that are susceptible to EMC interference without being affected

- The inherent electrical isolation means that the complicated story of earthing on PA systems is simplified to just the field area. In other words, the complication of Earth loop current over long distances is avoided.

Before going ahead with the design, one needs to answer some questions:

- Will multi-mode or single-mode fibre be used? Or is there a mixture?

- What connector types will be used on the fibre?

- Is a fibre redundant ring required?

These are the options using the COMbricks solution:

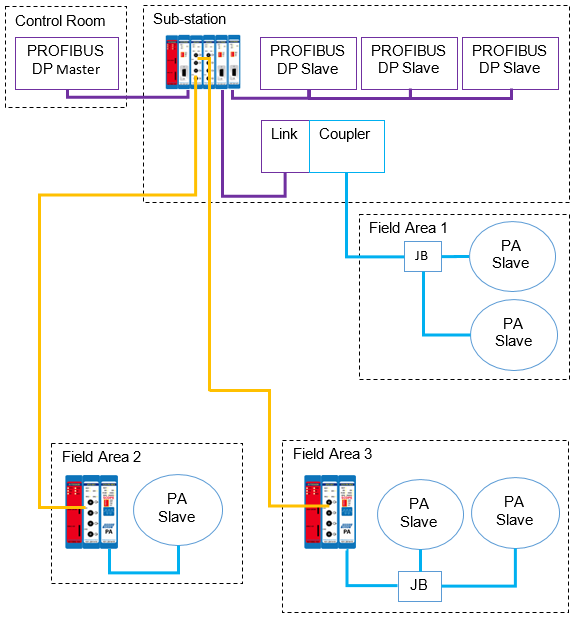

1) Multi-mode off one COMbricks fibre module in the substation (1 is spare):

COMbricks components used in the above implementation:

- x3 Head Station Type 1B (101-20011B)

- x3 PROFIBUS Fiber Optic Module (101-201510)

- x2 PROFIBUS PA link/coupler Module (101-201610)

- x2 SCOPE Repeater (101-201210) for connection of the DP devices in the substation

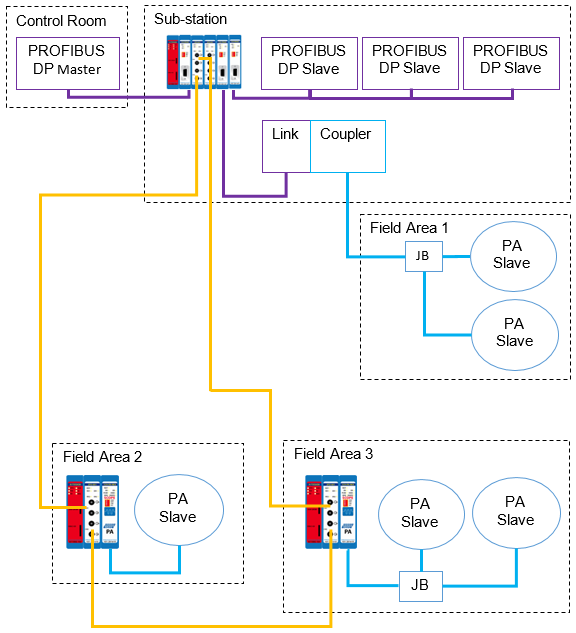

2) Multi-mode off one COMbricks fibre module in the substation (1 is spare), redundant ring:

COMbricks components used in the above implementation:

- x3 Head Station Type 1B (101-20011B)

- x3 PROFIBUS Multi-Mode Fiber Optic Ring Module (101-201530)

- x2 PROFIBUS PA link/coupler Module (101-201610)

- x2 SCOPE Repeater (101-201210) for connection of the DP devices in the substation

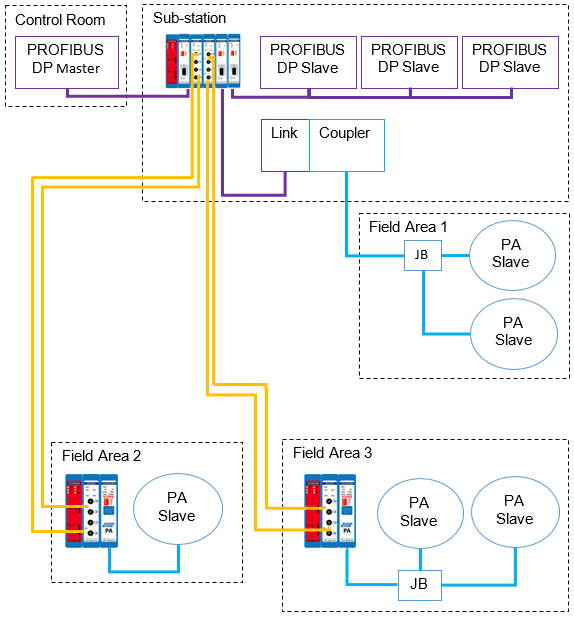

3) Multi-mode off one COMbricks fibre module in the substation, redundant ring for each field area:

COMbricks components used in the above implementation:

- x3 Head Station Type 1B (101-20011B)

- x4 PROFIBUS Multi-Mode Fiber Optic Ring Module (101-201530)

- x2 PROFIBUS PA link/coupler Module (101-201610)

- x2 SCOPE Repeater (101-201210) for connection of the DP devices in the substation

All of the above implementations could be implemented using single-mode fibre. Simply replace the multimode fibre module with the Single-Mode Fiber Optic Ring (101-201531).

4) It is possible to mix multi-mode and single-mode using the PROFIBUS Multi-Mode and Single-Mode Fiber Optic Ring Module (101-201532):

COMbricks components used in the above implementation:

- x3 Head Station Type 1B (101-20011B)

- x1 Multi-Mode and Single-Mode Fiber Optic Ring module (101-201532) in substation

- x1 PROFIBUS Multi-Mode Fiber Optic Ring Module (101-201530) for area 3

- x1 Single-Mode Fiber Optic Ring (101-201531) for area 2

- x2 PROFIBUS PA link/coupler Module (101-201610)

- x2 SCOPE Repeater (101-201210) for connection of the DP devices in the substation

COMbricks is a modular network component solution with the flexibility to meet almost any type of network architecture. All COMbricks head stations can be connected to the local LAN and be used to remotely access and view the health of the segments the COMbricks modules are attached to.

They can even be configured to issue email alerts if a PROFIBUS error has been detected on the segment so that it can be addressed before it causes a failure. This is part of your pre-emptive maintenance strategy.