For most of us, there was a stage in our lives, while growing up, that we went through, that involved us being the doctor and one of our friends being a deathly sick patient. Although we as juvenile doctors had very little experience and what I mean by very little is nothing at all! Usually, we would prod and poke our “patients”, and after some time, they would bounce back to life and we would all proceed to go and play in the sun.

Much of what I have seen with PROFIBUS problems can be compared to our “doctor! doctor!” days. Let’s run through a short case study…a problem occurs onsite…”THE NETWORK HAS DIED,” what follows is an assault of prodding and poking until miraculously the network is up and running leaving all involved feeling exhilarated over a job well done but not knowing what was done to fix it.

Here are some practical tips on how to help solve your problem and hopefully leave you feeling a little bit less like you are alone in the dark:

- The blind leading the blind

If you know nothing about PROFIBUS, be honest and call an expert. I have never heard of anyone taking their Lamborghini Murcielago to a chop shop on the side of the road to get the exhaust spot welded.

- Your weapon of choice

Just like every good doctor has his/her stethoscope and surgical blade so too do you need yours. Unfortunately, most of the time people want to operate on their PROFIBUS network with a spoon and end up bludgeoning it to death. It is important to know the different options that you have when it comes to PROFIBUS diagnostic tools.

There are two different types of test tools, a physical line tester and a message/protocol analyser. Both are invaluable and are required to diagnose the full spectrum of problems that you may face. Some of the functionalities that you would want to look for in a message or protocol analyser are a bar graph, oscilloscope, message recording, reporting, trigger ability to start message recording when a fault occurs and preferably some controller functionality.

- Be doctor doc

Know what the PROFIBUS installation requirements are. I can’t stress this enough, most faults are caused by bad installations and lack of knowledge. Some of the most common errors are incorrect terminations, and PROFIBUS cables cables tied to high-voltage lines running for hundreds of meters. Understanding what the “dos and don’ts” of PROFIBUS are will help you to identify where the problems lie.

In most cases, this should be evident by looking at these 5 tips and tricks.

- Tip 1: Walk the line

It’s important to know what is physically happening along the PROFIBUS cable. Things to look out for, terminations, stub lines, devices that don’t use D-Sub connectors because they may have a built-in termination switched on, location of high voltage lines, lengths of PROFIBUS cable, amount of devices in the segment and the type of cable used. Your problem may be found by simply looking at the network. - Tip 2: Best bar around

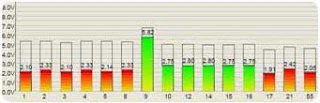

Look at the bar graph to determine if any of the voltages are below the 2.5v threshold. If there is one device that has a low voltage level then focus your attention on that device. If multiple devices have low voltage levels then have a look at that specific segment. Unplug one device at a time to determine if that device may be causing the problem.

If the voltages all the voltages are fluctuating then there is a large chance that you have a dirty/floating earth or if one device’s voltage is fluctuating a lot then you might have a duplicate address on that device.

- Tip 3: Catching the perfect wave

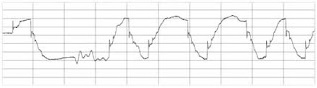

Have a look at the signal waveforms, the waveform should be a square shape. A small spike may be present because you have plugged in the diagnostic tool. If the signal is not square and contains reflections (wave-like signals that die out then are repeated) or spikes, look for incorrect termination, over-termination or stub lines. These types of errors can easily be seen on an oscilloscope.

The advantage of using a PROFIBUS test tool oscilloscope is that you can look at the signal waveform for each device as opposed to seeing all the waveforms and not knowing which device that specific signal originated from. Having a physical line PROFIBUS tester is helpful in these situations because you can test if the terminations are in the correct locations and not over or under-terminated.

- Tip 4: Track and trace

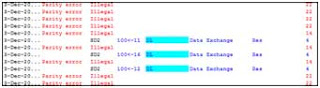

Use your message trace to record messages. This will give you an excellent idea of what the error may be. The two most common types of errors are broken messages and configuration errors. Broken messages are predominately caused by noise in the cable, breaking the messages or by devices speaking at the same time causing message collisions. Configuration errors will not allow the device to enter data exchange or if the device was in data exchange and something broke in the device, then the device will fall out of data exchange.

- Tip 5: Isolation

In some situations, it may be difficult to find what the cause of the problem may be. Most modern PROFIBUS D-sub connectors break the outgoing line when the termination is switched on. This is extremely helpful and allows you to add one device to the network at a time. By doing this you should be able to find which device is causing the problems on the network. - Tip 6: I need backup

If all else fails…give us a call we are more than willing to help you in your desperate time of need.

If you are looking for some PROFIBUS test tools, we sell and use them daily for audits and training.