When delegates visit the IDX Academy in South Africa for training, they are always encouraged to bring their piece of equipment along with which they might be having trouble getting communications going – or even just understanding the data it produces.

At the end of a gruelling PROFIBUS Engineers Course, two delegates from ABB stayed behind to see how they could do a proof of concept to show that their AO2020 Analyser connects to and makes data available on PROFIBUS. They already had a PROFIBUS Master Simulator from HMS.

Using the simulator, you can load the GSD file and connect to the PROFIBUS address of the Analyser via a piece of PROFIBUS cable – easy! The raw data is produced in hex and binary – this can be tricky to understand. We were reading 41 A8 CC CD (hexadecimal), but knowing that the data type is an IEEE Floating Point value from the manual and entering these values into an online IEEE float to Hex calculator gave us a value that made sense: 21.10! They are now ready to do a proof of concept for any customer that is using PROFIBUS.

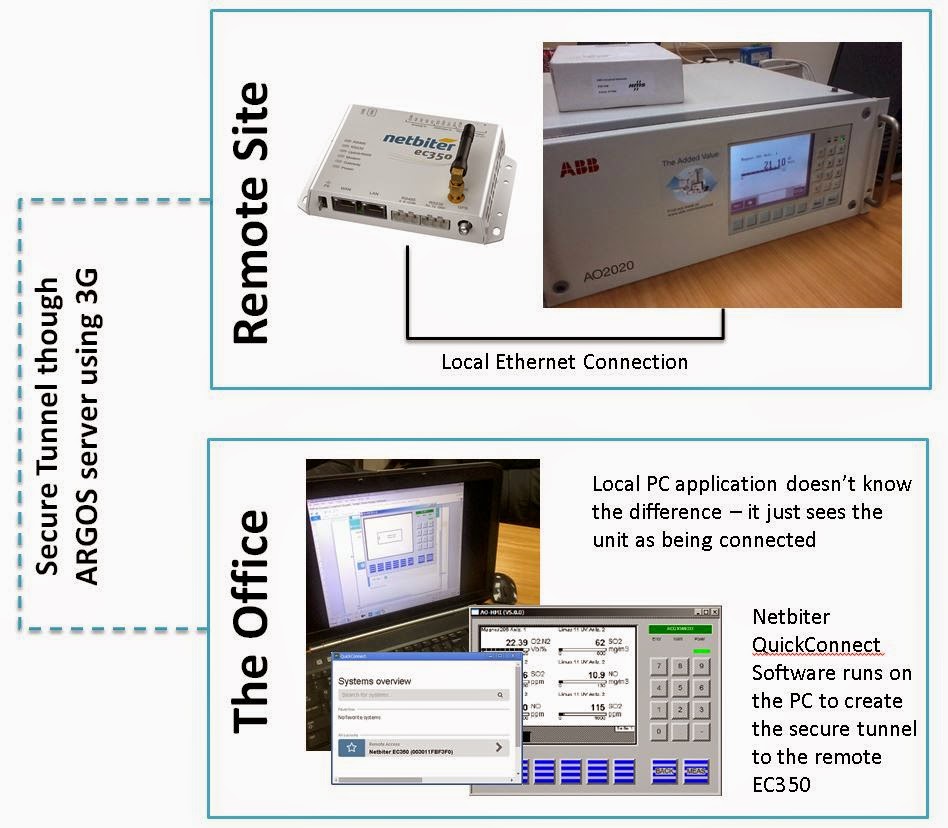

Separate to this there is an Ethernet connection available that can connect a PC-based HMI simulator to the AO2020. Now the question was, could one use this software on a PC in your office and connect to the AO2020 sitting at a remote site? The new EC350 with its remote access capabilities can do this. It’s like having a long Ethernet cable connecting your PC to the remote device!

The Netbiter EC350 has an Ethernet port to connect to a local LAN (the analyser in this case) and a WAN port to use the internet connection of an office LAN. After successfully connecting using this method, the WAN access was replaced with 3G access by inserting a SIM card into the EC350. Success! This proved that the Netbiter EC350 could be used to create a secure Ethernet tunnel between a PC in an office and an ABB AO2020 analyser in the field.