When an organisation decides to introduce a different Plant Data Historian the requirement to retain visibility and access to existing historical data can be a challenge. There might be multiple years’ worth of valuable plant data associated with the legacy Plant Data Historian which somehow needs to be migrated to the new Plant Data Historian.

Typically the same or a similar tag set is established on the new Data Historian and plant data will start to be recorded in the new system. There might be a switch-over period where both the old and new systems record data until the Plant is convinced that the new system is fully commissioned. All reports and web portal views will now reference the new Plant Data Historian.

Data migration is typically done in one or two tranches and the legacy Data Historian is finally decommissioned and all costs associated with its maintenance cease.

In our experience, the users of plant data are not empowered to attempt this onerous task on their own and its complexity can be a major distraction to their already busy schedules.

The IDX Tag Manager and IDX Historian with its Historian Data Migration Tool enable IDX to offer an outsourced service to cost-effectively and reliably handle this process for a Plant.

There is no requirement for the customer to purchase any hardware or software, they simply need to provide access to the legacy and new Plant Data Historians.

Rather the customer will be charged a fee that will cover the equipment rental and engineering effort to complete the data migration.

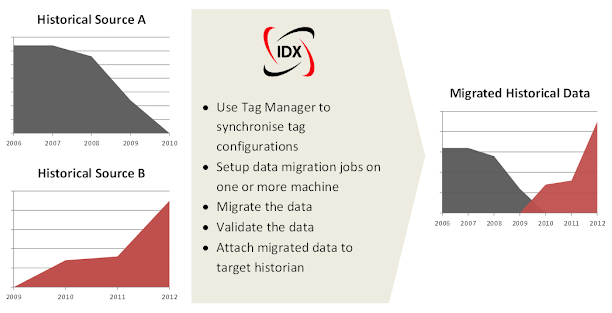

Migration process overview when migrating and merging two historical sources into a single target using the Migration Tool.

The data migration is set up offline on one or more virtual machines and when ready migrated data is “attached” to the new Plant Data Historian and can be accessed by users.

A typical plant data migration project for 50,000 tags over 4 years would take 1-2 months to complete.