A client required some data on his SQL database to be sent to his PLC. He had a few sensors inserting data directly into his SQL database and he needed this data to be processed by his PROFIBUS PLC controller so that the correct actions could be taken.

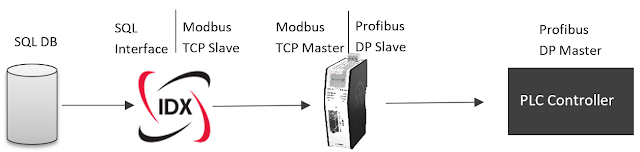

The solution was an SQL to PROFIBUS bridge. IDX provided custom software that would extract the SQL data in real-time and expose the extracted data as a Modbus TCP device. The data could be converted to a PROFIBUS protocol, using a gateway such as the Anybus X-Gateway AB9001, and then be sent directly to the PLC controller.

IDX 8

We provided the client with a custom software called IDX 8 which is offered by IDX. It contains a suite of functionalities which includes tag management, remote monitoring, historian, alarms and events, data exchange, and more. The function of interest here is its data exchange component which allows for real-time data to be shared with different systems.

After the client installed IDX 8 on his test server, which he brought to IDX for a demonstration of our proposed solution, we continued to set up IDX 8 to extract the SQL data and expose it as a Modbus device , the steps for the setup are as follows:

- Setup Data Exchange service

- Setup SQL interface

- Setup Modbus Device interface

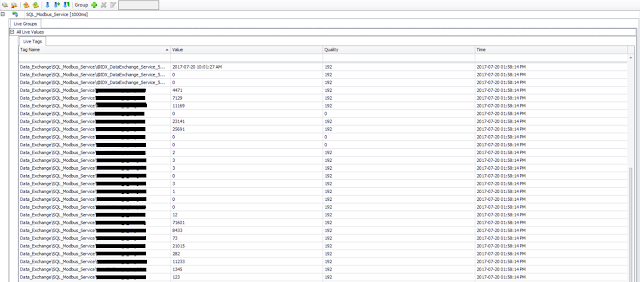

After the setup, we demonstrated to the client that the data was indeed being extracted from the SQL database. This is shown below using the “Live Tag View” function that IDX 8 supplies:

The Anybus X-Gateway AB9001

To configure the AB9001, we require an “IPConfig.exe” tool supplied by the distributor of the product, HMS Networks, and a web browser. We used the “IPConfig.exe” tool to set up the IP address of the AB9001 gateway and then configured the Modbus settings using a web browser, by accessing the device’s web interface using the assigned IP address.

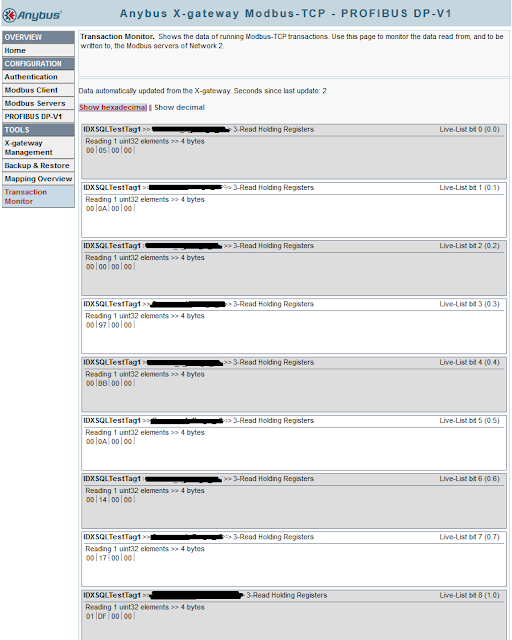

The hardest part of this process was the mapping of the Modbus transactions to instruct the Modbus controller to read the correct values from the correct Modbus device registers. Once that was done, we used the “Transaction Monitor” function that is provided by the device through its web server to demonstrate to the client that the values read by IDX 8 were indeed being exposed as a Modbus device. This is shown in the image below:

Setting up the Anybus X-Gateway as a PROFIBUS Device

Setting up the PROFIBUS DP device on the Anybus X-Gateway was done by just assigning a device address to the device on its “PROFIBUS DP V-1” menu in its web server. After that, we then checked the mapping of the Modbus Controller registers to the PROFIBUS DP Device using the “Mapping Overview” page provided by the web server.

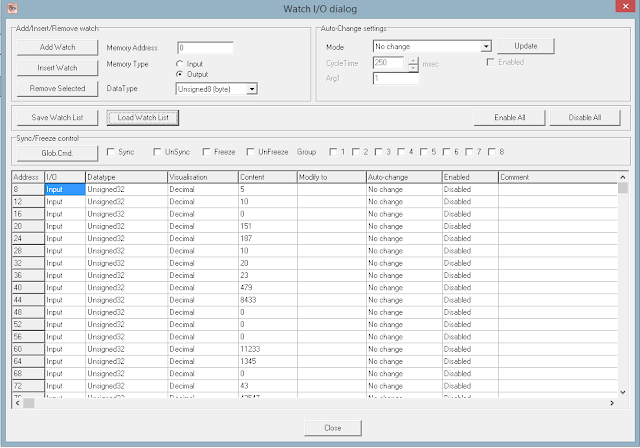

To confirm that the Gateway was indeed ready for PROFIBUS communication, we set up a PROFIBUS Controller simulation using a tool called ProfiTrace from Procentec. We demonstrated to the client that the PROFIBUS Controller was in data communications with the Gateway and that data that was originally from the SQL was indeed being sent through to the simulated controller, this is shown in the image below: