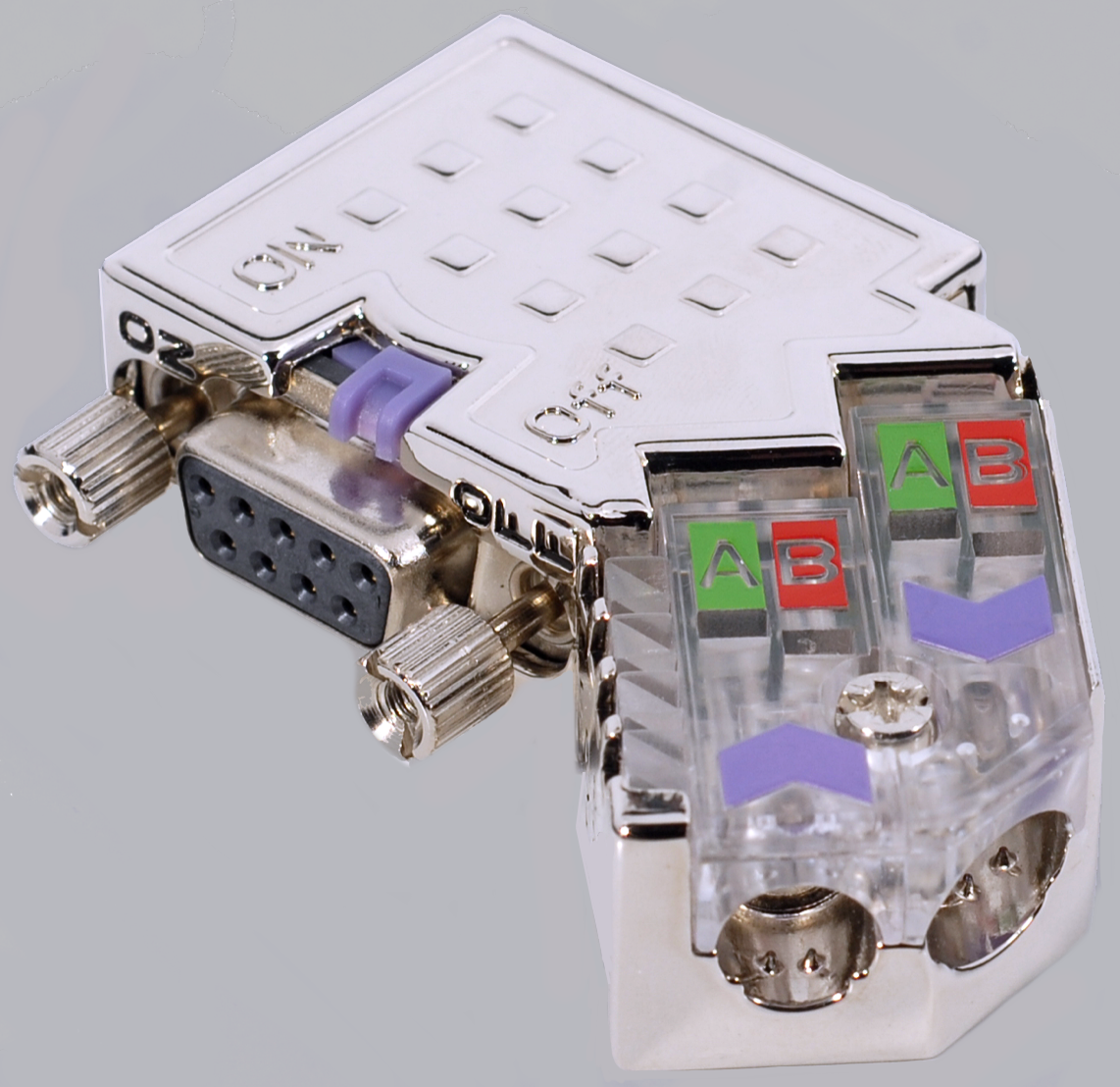

The high-end PROFIBUS Connector EasyConn PB from Yaskawa (Profichip) has various features that speed up installation and troubleshooting:

- Status LEDs which are visible from both sides indicate bus and device status.

- A piggy-back connector with a 90-degree cable outlet provides easy access to the integrated PU/diagnosis socket so that no additional hub is required.

- The full metal case ensures high noise immunity.

- The switchable termination resistances which are accessible from both sides are activated by the plug with slide switches. In this way, testing of the Profibus communication can be executed without removing plugs or cable, the cable ducts are equipped with a transparent cover so the correct correlation of the coloured cable cores is visible.

What do the Status LEDs mean?

- PWR (Yellow LED) – Shows the voltage supply of the device.

- TxD (Green LED) – Shows bus activity (TxD). It seems as if communications are active.

- TERM (Yellow LED 2) – Informs whether the termination is switched OFF or ON.

- ERR (Red) – Indicates whether there is a wrong termination resistance or a false surge impedance that influences the bus transfer. Connect a network analyser to diagnose the faults.

What configurations do they come in?

The 180-degree PROFIBUS connector is perfect for those situations where you need to connect to a PROFIBUS device that has limited space. This orientation of the connector is also useful in the building of stub tap connectors for Profibus test equipment.

The 90-degree PROFIBUS connector is the most popular seller out of the EasyConn range as most devices is built to accommodate this type of connection. It allows for easy connection of PROFIBUS test equipment through its piggy-back connector.

In some situations, especially inside panels where there is limited space, the installer is required to reduce the bend radius on the PROFIBUS cable. The A 45-degree PROFIBUS connector is well suited for these situations.