What happened to the serial port on my laptop? Indeed it seems that our PCs are upgrading faster than the industrial devices we still use. Being an Industrial IT company, daily we still have to use HyperTerminal and other serial-based software to configure devices and get information out of systems such as belt scales and gateways.

So what if I need to get a device that speaks serial onto an industrial Ethernet-based protocol such as PROFINET, MODBUS TCP, EtherCat or Ethernet/IP? Well for that we can use the Anybus Communicator, which we have spoken about before. That is a protocol converter. Incidentally, this device is easily configured using a serial port, but for that, I need to have a serial port on my PC. (The new generations of these gateways are moving to USB, but what about all those thousands that are in the field already?)

One solution is to buy a USB to Serial Converter, but anyone who has used one of these will most likely agree that they can be quite troublesome. So what’s my other option? My other option is to get a Serial to Ethernet converter such as the Anybus Serial Server. It can convert RS 232 to Ethernet or RS 485 to Ethernet.

It’s also so easy to use:

Step 1) Power it up with 24V and connect it to your LAN or to your Ethernet port

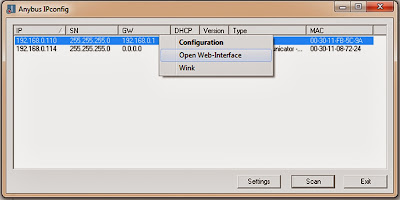

Step 2) Install and run the free AnybusIP config tool. It scans by MAC address so you can use this to discover what the IP address of your serial server is. Here you can change the IP address and open up its web interface from your browser.

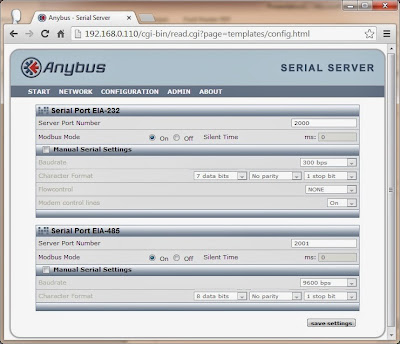

Step 3) Click on “Configuration” and configure the ports you are going to use. I used port 2000 for the RS-232 port, and port 2001 for the RS-485 port. The server is now ready to use.

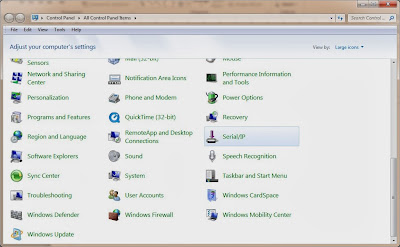

Step 4) Now we have to tell our computer where these virtual com ports are. Install and run the Serial/IP driver. You can find it in the Control Panel.

Step 5) Choose your COM port and fill in its IP address and port number.

Here’s a tip: Choose port numbers that are less than 10!

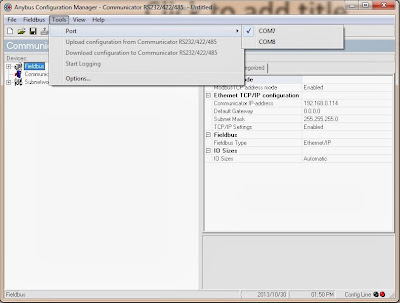

Now I’m ready to use my COM ports. In the below example, I am now able to program my Anybus Communicator through a LAN with either COM7 or COM8. Since COM 8 is an RS485 port, I won’t be able to use that to program my Anybus communicator, but it is useful for other applications. In our Anybus Communicator and Modbus training, we used to run a device simulator through this port.

Making Serial COM ports available through a LAN means that you can program devices that are located long distances away. We used the Serial Server to program an Anybus Communicator which was located on a distant conveyor belt, from the comfort of an air-conditioned control room.