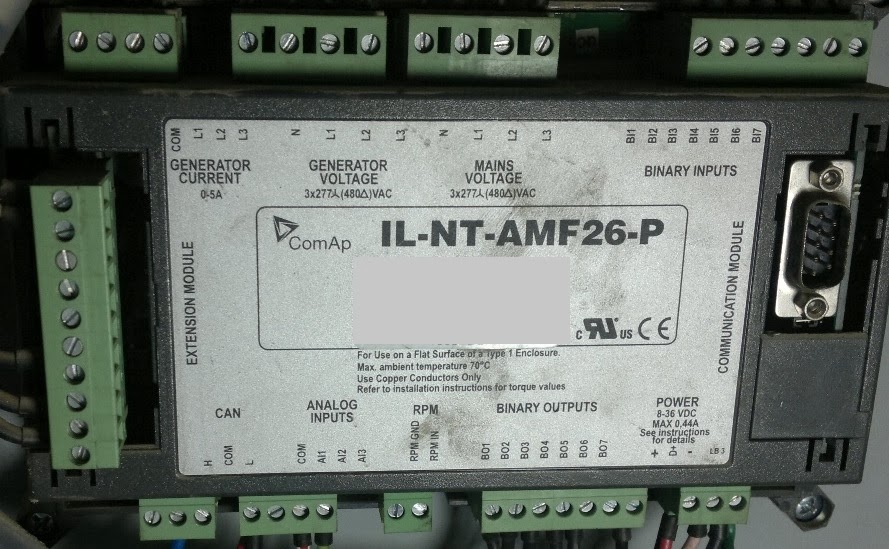

In this blog, I will discuss the steps involved in getting the Netbiter to record and display values coming out of the ComAp Generator Panel, so that one can do remote monitoring and control of the generator. The Netbiter Model used in this case is the EC220 and the panel used is the InteliLite AMF 26 P. The steps followed here can be applied to any MODBUS device due to the generic nature of the Netbiter.

Step 1 – Physical Connection

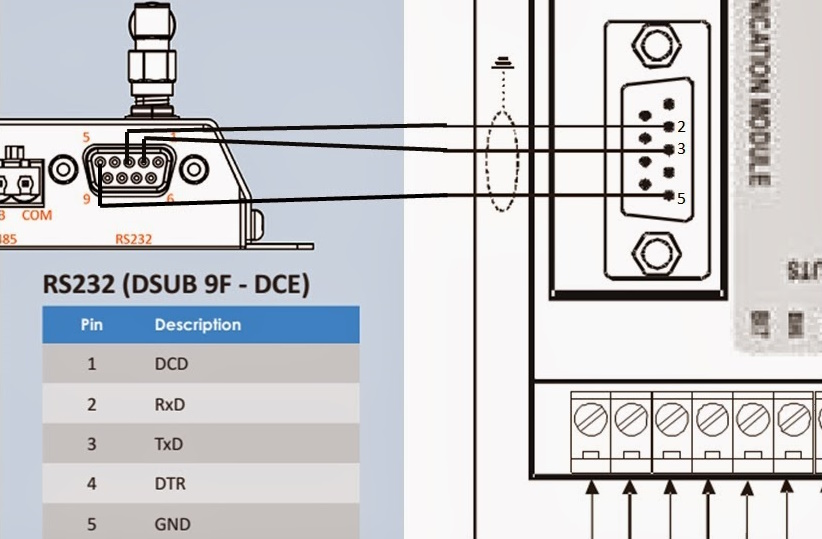

Check that the Control Panel has a communication module attached to the back of it. You will need to establish the medium (RS458/RS232) and the protocol spoken (MODBUS RTU/ASCII) – all of this information will come from the user manual of the generator. Finally confirm the communication settings (baud rate, parity, stop bits, etc) – these can sometimes be changed so check what they are on the actual panel. In this case, we have the following settings:

MOUBUS RTU over RS232 (you’ll need an external converter to convert the RS232 to RS485).

Baud rate: 9600bps, 1 start bit, 8 data bits, 2 stop bits. (since we have 2 stop bits, we do not have parity checking).

Tip! Make sure that the RS232 data cable is shielded and that the shield is properly earthed. Also, the cable should not be too long (max 10-15m, but this depends on the application) and should not run near any high-voltage lines. 25 to 400 V AC: at least 10cm from the data cable. Anything above 400V AC: 20cm or more from the data cable.

The physical wiring should be done accordingly:

Step 2 – Creating the MODBUS Template

Now that you are physically connected, the next step is to create the MODBUS register template in Argos. This template is used to tell the Netbiter which parameters will be of interest to the user. To create a template you will need to get hold of the MODBUS register table from the device manufacturer (The Netbiter is a MODBUS Master which queries MODBUS Devices – in our case, the device is the ComAp panel).

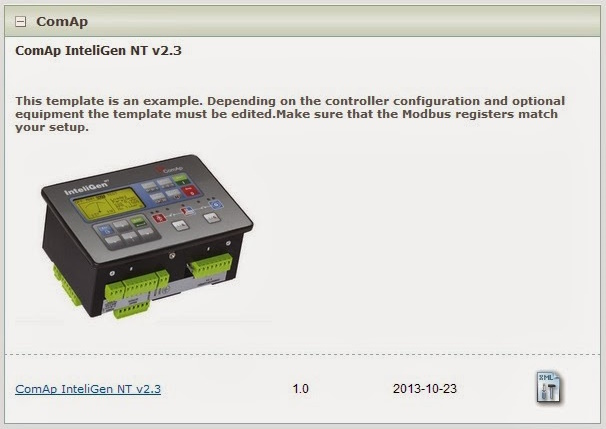

Tip: You can sometimes save yourself a lot of time by checking to see if someone has already created a template for you. These templates are stored on the Always check this list first: http://support.netbiter.com/device_templates.cfm

Even if you have a different model, you can sometimes reuse one of these templates. Sometimes the descriptions are in another language, but even these are re-usable. In January 2014, this was the only template available – we will try to reuse it. So download it and save it to a directory on your computer.

Step 3

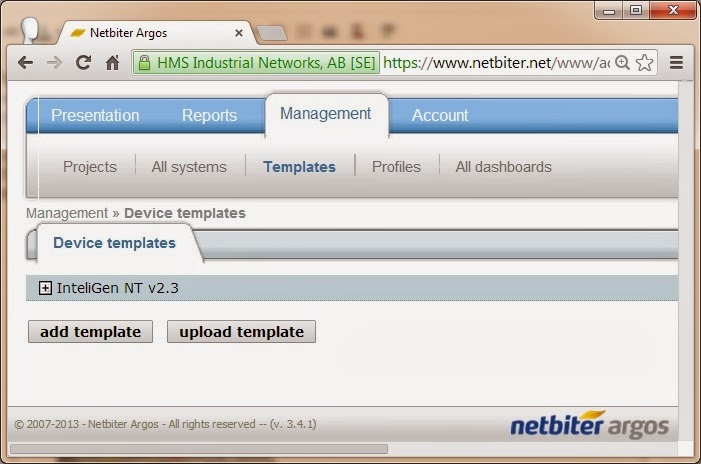

Log into www.nebtiter.net with your free account. You can only edit/create templates if you logged in as an administrator. Once there, click on “Management” and then on “Templates”. Upload the template you have saved.

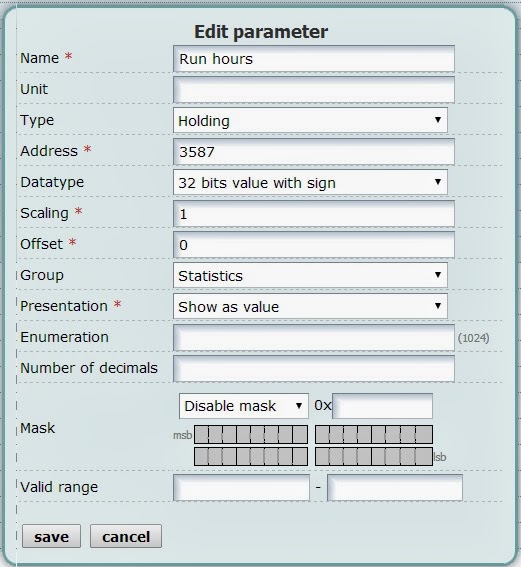

Feel free at this point to expand the template tree view and see what groups are available. Remember, your device might not support all the functions of the template. You can within these groups, edit the individual parameters and adjust their Modbus register address, the device name, scaling, etc. Here we have the “run hours” parameter under the group “statistics”:

Feel free to create your parameters or delete ones that you will not use. These will be used later when we create a profile.