Not only is it possible with IDX but simple, quick and cost effective.

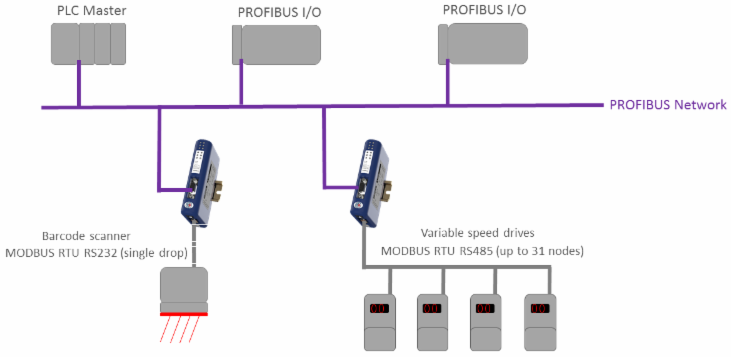

Anybus is your ideal solution, dominant when it comes to converting between Fieldbus, Ethernet and serial protocols. Integrate your RS232,422 & 485 equipment to a PROFIBUS/PROFINET control system without any changes to your device.

Simply connect, configure and you’re done! Simply IDX it!

Some of the features and benefits you can expect from the Anybus Communicator include:

- Save time and unnecessary development when integrating your device into PROFIBUS/PROFINET

- MODBUS RTU configuration wizard

- Ability to configure ASCII or vendor specific protocols

- Multi language support

- Handy save and load function allows for a completed configuration to be utilised on alternate installations

- Serial line listener and built in checksum calculator for diagnostics and

troubleshooting - No high level programming skills are needed to set up the Anybus communicator. the Anybus device is configured utilising included user friendly windows software (Anybus Configuration Manager)

- 3 year guarantee

Case Study:

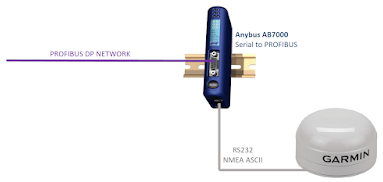

Using the Anybus Communicator to get NMEA GPS data from an Industrial GPS antenna into PROFIBUS

Recently IDX was contacted by a client that wished to get NMEA data strings from a Garmin industrial GPS receiver into the plants PROFIBUS SCADA system. It was quickly identified that an AB7000 – Anybus Communicator would be the most effective device for the job.

Within the NMEA protocol, various messages are pushed along the data line, each ASCII strings provides new information. An Example of one of these strings could be a RMC (Recommended Minimum Data), this will look similar to:

$GPRMC,123319,A,4807.038,N,01131.000,E,022.4,084.4,230394,003.1,W*6A

Where:

- RMC: Recommended Minimum GPS Data

- 123319: Fix taken at 12:33:19 UTC

- A: Status A=active or V=Void.

- 4807.038,N: Latitude 48 deg 07.038′ N

- 01131.000,E: Longitude 11 deg 31.000′ E

- 022.4: Speed over the ground in knots

- 084.4: Track angle in degrees True

- 230394: Date – 23rd of March 1994

- 003.1,W: Magnetic Variation

- *6A: The checksum data, always begins with *

After sniffing the ASCII string using software included with the Anybus communicator, we were able to truncate and map relevant values through to the Profibus driver. The main interest of the plant was to know the location of their rail equipment at all times, in order to prevent a collision. Thus the only relevant info would be the latitude and longitude, in addition we also mapped a few status bytes and integrated a checksum to confirm the data being read as accurate.

This application has been repeated in thousands of separate installations, ranging though various applications, from weigh scales, to scanners, to VSD’s and now GPS systems.