Are your PROFINET assets installed within specification? How do you ensure high network availability?

PROFINET is a very widely utilised Industrial Ethernet technology and is respected for its advanced diagnostics, simple commissioning, and robustness within various industrial environments.

Within the installation and implementation of a PROFINET network, various precautions should be taken, and standards put in place that should be adhered to. Without such adherence to the guidelines, communication issues may arise.

Minimising interference and noise

Cable clearance guidelines

PROFINET cables running near high-voltage machinery and unshielded high-voltage cables can cause severe EMC interference and disruption of network communications.

- Always maintain a minimum 20cm separation distance between PROFINET cables and un-shielded supply cables (>400V).

- Fibre optics should be considered when running through an area with a substantial risk of EMC interference.

- Utilise earthed metallic cable trays or conduits to protect cabling from interference when running between cabinets.

Proper grounding techniques implemented

Proper grounding is crucial for all PROFINET Installations, cables should be earthed at each device, and as the cable enters and exits cabinets to the functional earthing system.

Why is this important? PROFINET cables have a shield that surrounds the cores, to protect the signal from noise and EMC injection. The shield carries any pickup to Earth, the path from where the noise is picked up, to where it is drained to Earth should be as short as possible.

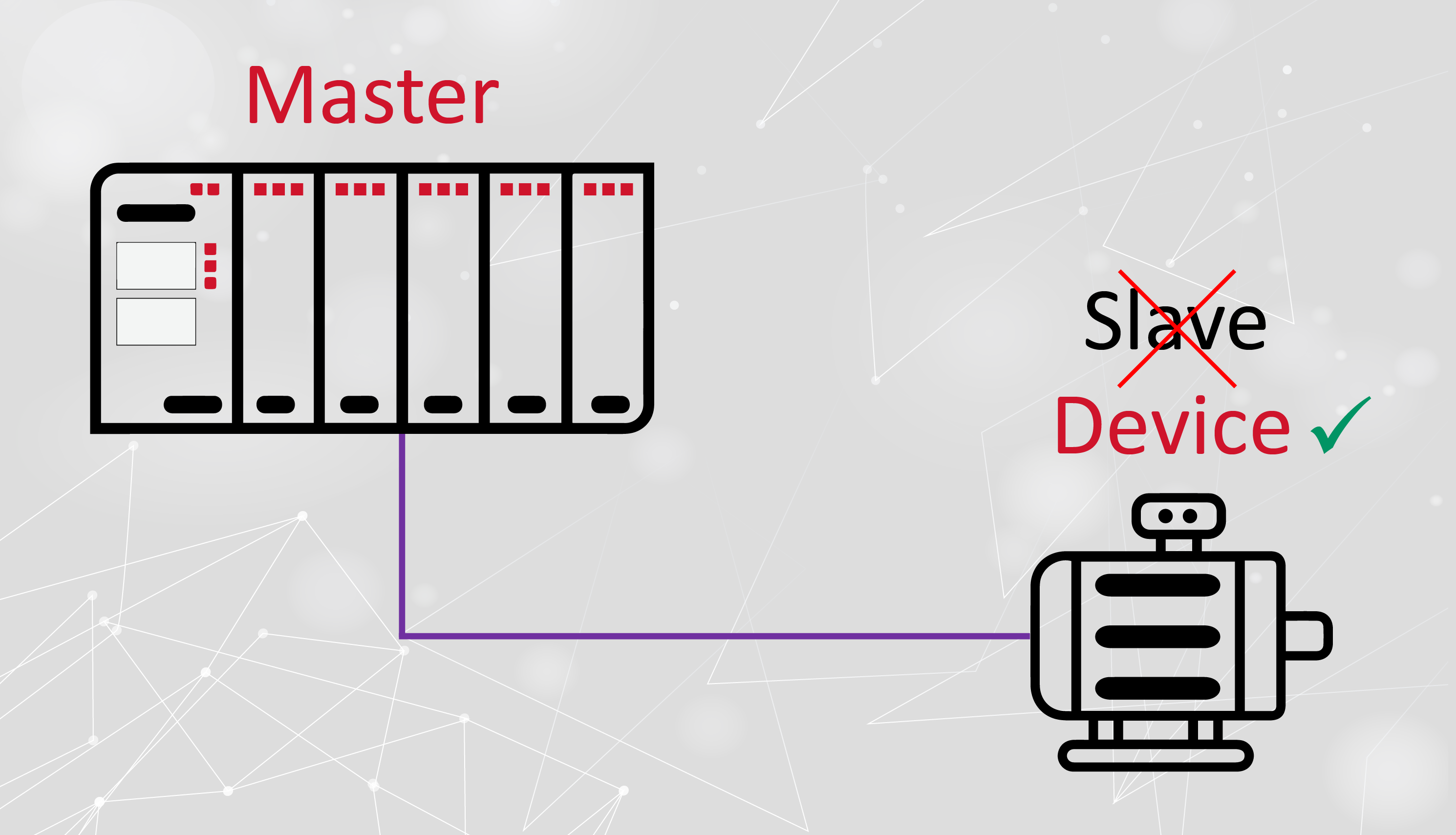

Utilise the right network components for your PROFINET Network

Connectors

Bad connectors = Bad communications!

Always use PROFINET connectors, standard RJ45 connectors are not acceptable for industrial environments:

- Industrial RJ45 connectors have a steel housing that earths the cable shield within the device.

- Connector offers cable strain relief, connectors clamp onto the cable sheath to ensure the cores do not slip loose under movement device or cable movement.

- Rugged industrialised design

When building up cables, be sure to utilise an appropriate PROFINET stripping tool, to reduce accidental wiring faults and ensure a consistent connection at each device.

Managed switches

Although utilising managed switches is not a prerequisite for a PROFINET network, it is extremely useful and crucial for consistent uptime, high network availability and ease of maintenance and troubleshooting. An unmanaged switch has no built-in intelligence, except to send incoming Ethernet frames out to the right port (the Port the destination device is connected to).

Managed switches add intelligence, supporting many useful IT protocols. Some of the features that a managed switch will offer you over an un-managed switch:

- Integrated SNMP (Simple Network Management Protocol) and LLDP (Link Layer Discovery Protocol), specialised protocols allowing users to retrieve data and statistics saved within switches, such as retries, real-time bandwidth utilisation, and network topology.

- Mirror port, a managed switch will allow you to set up a mirror port that channels all the switches’ data to a single configured port. This is extremely useful if you want to run diagnostics on your PROFINET network without interrupting transmission. You can utilise PROFINET Engineering tools such as Procentec Netilities to monitor all network traffic on a mirror port and provide valuable diagnostic information to the user.

- Certain managed switches can be utilised for the creation of redundant network structures.

- Advanced features, may include loop protection, advanced VLAN functionality, more precise diagnostics and control of network traffic.

Precise commissioning, maintenance and diagnostic tools

With any industrial automation technology, specialised tools, software and network components can assist you with various tasks, from network commission, to upgrade and to run diagnostics. There are plenty of great tools available on the market. Some of the more popular tools imperative for your installation are listed below:

Netilities

Dedicated PROFINET diagnostics engineering tool. Generating a live list and providing various crucial statistics about the network. Netilities are crucial when commissioning PROFINET networks, providing maintenance tasks and troubleshooting problems. You can interface Netilities with your network using a standard Ethernet/WLAN port on a PC, or the ProfiTap for a secure connection.

ProfiTap

If you don’t have a mirror port available on a managed switch by the PLC, you may require a dedicated tap device, that allows you to monitor traffic and information running through the network. A tap device can also be a more secure way to connect your PC to your industrial network, allowing only one-way traffic for monitoring.

Atlas

Permanent diagnostics monitoring, trending and network overview. The Atlas will assist you in managing and maintaining large factory networks by providing you with insight and knowledge of the network’s health, state and performance. The Atlas offers a unique Quality Factor rating, that takes a weighted algorithm of the network performance and risk and displays this in a user-friendly and interpretable manner.

Internationally certified training ensuring site competence

One of the first steps all organisations should take to ensure a successful PROFINET integration is to ensure all stakeholders involved with the implementation have the necessary training, foundation understanding and certification.

The PROFINET / PROFIBUS Competence Center of Southern Africa runs the Certified PROFINET Engineers Course periodically on our scheduled course at our offices, alternatively at a site’s convenience.

Why should I attend training?

The certified PROFINET Engineers course provides the foundation for clear site competence, knowledge and know-how. Training is crucial for any installers, designers and C&I Maintenance staff.

What will be covered?

The PROFINET Engineers Course combines in-depth theoretical knowledge along with hands-on practical exposure.

How long is the course?

The Certified PROFINET Engineers Course spans over 2.5 days, with a written and practical examination to be completed on the last day. Lunch will be provided each day

How do I sign up?

Contact the IDX Academy to obtain additional information, booking forms and pricing.

Email: academy@idx.co.za | Phone: (+27) 11-548-9960 | Website: www.idx.co.za